Artificial Stone for Commercial Projects: The Ultimate Buying Guide

Selecting stone materials for commercial projects is one of those decisions that looks straightforward on paper but often turns into a risk-heavy task once execution begins. Texture samples look refined, catalogs promise premium results, and finished spaces can indeed feel upscale.

The trouble starts when material choices don’t match real usage: color inconsistency across batches, materials substituted without notice, or physical performance that fails under daily wear. Costs rise, schedules slip, and maintenance becomes a long-term burden.

This guide is written from a manufacturer’s perspective, based on real project experience. It explains how artificial stone and engineered stone perform across commercial applications, how to avoid common purchasing traps, and how to evaluate suppliers as long-term risk-control partners rather than simple material vendors.

Artificial Stone & Engineered Stone: An Overview

Artificial stone is a broad category that includes engineered stone, quartz surfaces, solid surface materials, terrazzo, and other composite stone products manufactured under controlled conditions. Compared with natural stone, artificial stone offers stable color, consistent structure, predictable physical performance, and easier large-scale supply.

Engineered stone, especially quartz-based products, is widely used in commercial interiors due to its high density, low water absorption, and strong resistance to wear, stains, and impact. For projects that require consistency across hundreds or thousands of square meters, engineered stones often deliver better cost-performance over the project lifecycle.

Engineered Stone Factory in China

Choosing the Right Stone by Application

Different commercial spaces face very different physical demands. Climate, foot traffic, hygiene standards, and maintenance expectations all influence the correct material choice.

Kitchen and Bathroom Areas: Durability & Easy Cleaning

Designed for high-use environments, kitchen and bathroom areas call for surfaces that combine long-lasting durability with effortless cleaning. Quartz stone and high-performance artificial stone deliver a perfect balance of strength, hygiene, and refined aesthetics.

Why they work

● Extremely low water absorption (often below 0.01%), preventing stains from oils, sauces, and liquids

● High hardness (Mohs 6–7), resistant to knife scratches and daily impact

● Seamless fabrication for sinks and countertops, reducing joints where bacteria and mold can accumulate

Marble and travertine have higher porosity. Acids such as vinegar or citrus juices can etch the surface. If natural stone is specified by the project owner, surface treatments such as crystal surface or hardened coatings can reduce permeability and improve durability, extending service life while preserving natural aesthetics.

Quartz Stone Kitchen Countertop Factory

Commercial Flooring: Hotels, Shopping Malls, Public Areas

Commercial spaces such as hotels, shopping malls, and public areas demand flooring that combines exceptional durability with lasting visual appeal. High-performance artificial stone and terrazzo flooring offer the perfect solution, delivering superior wear resistance, easy maintenance, and a polished, professional look that stands up to heavy foot traffic.

Why they work

● High abrasion resistance for continuous foot traffic

● Strong compressive strength, suitable for carts, equipment, and heavy loads

● Seamless installation options that reduce dirt accumulation and simplify cleaning

Materials requiring caution

● Travertine and some natural stones can lose gloss over time due to micro-scratching

● Thin sintered slabs may be brittle under point loads

● Natural fissures can propagate under pressure, increasing the cracking risk

Maintenance downtime in commercial venues directly affects revenue. Artificial stone minimizes long-term upkeep and operational disruption.

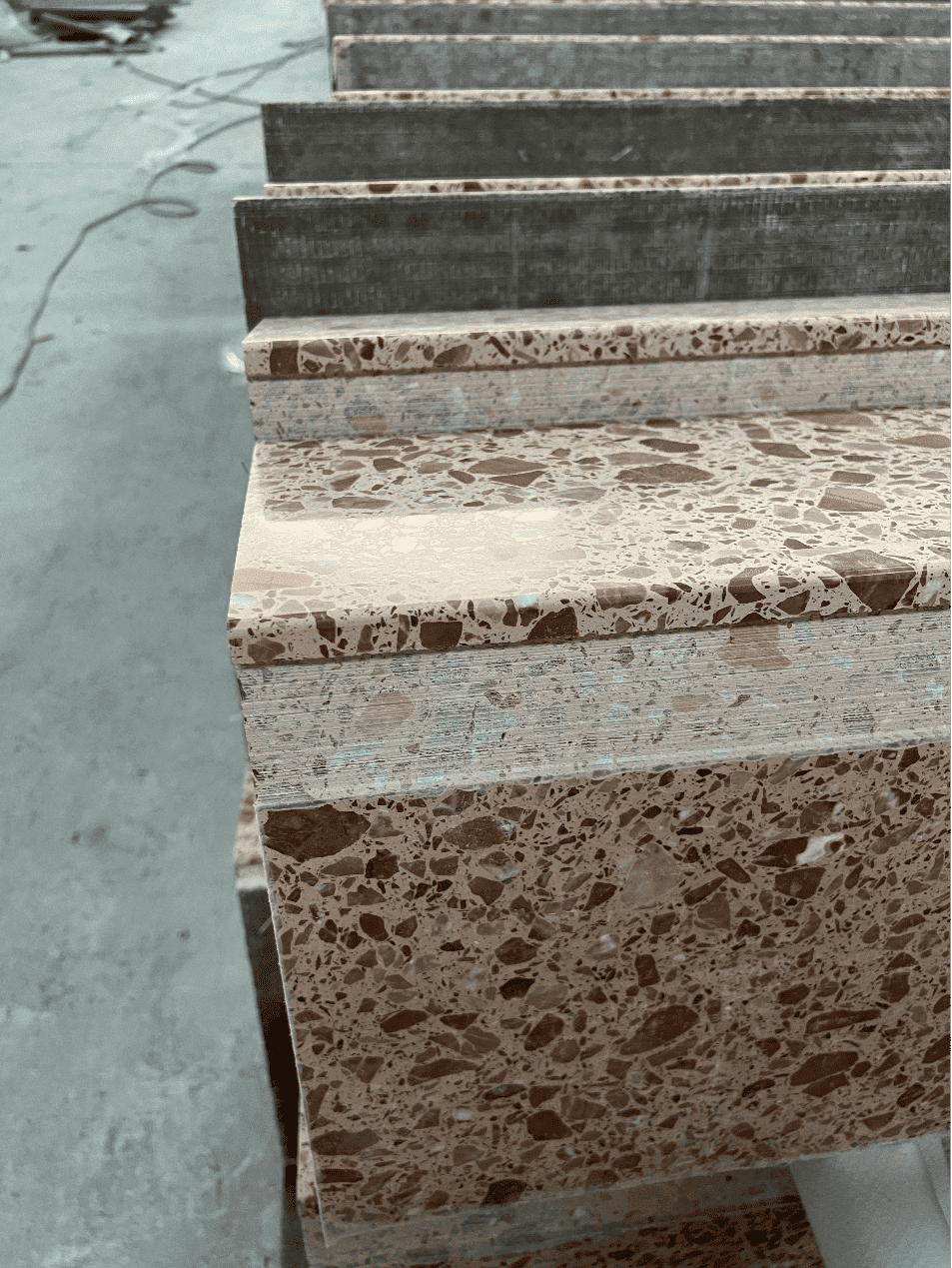

Terrazzo Flooring Stair For Shopping Mall

Commercial Wall Applications: Balancing Texture and Practicality

Walls in commercial spaces need to balance aesthetic appeal with practical performance. Suitable options include:

Ultra-thin flexible stone – Lightweight and versatile, perfect for creative wall designs without compromising structural integrity.

Marble – Timeless elegance that elevates any interior with natural sophistication.

High-performance artificial stone – Durable and low-maintenance, ideal for high-traffic or high-use areas.

Semi-precious stone panels – Adds luxurious textures and unique visual interest for premium spaces.

Travertine – Natural warmth and subtle patterns that create inviting, refined interiors.

Cement-based stone – Modern, industrial look with excellent durability and easy upkeep.

Application advantages

● Lightweight solutions reduce structural load

● Artificial stone provides consistent color and stable dimensions

● Semi-precious stones offer light-transmitting effects for feature walls

● Cement stone supports large-scale applications with strong fire resistance

Risk notes

Soft natural stones can be scratched easily in high-contact zones. Heavy natural cultural stone carries fall risks on exterior walls and requires careful anchoring and maintenance planning.

Cement Stone For Wall Cladding

Furniture and Countertops: Zero Penetration, Chemical Resistance

Furniture and countertops require surfaces that resist stains and chemicals, making quartz stone, premium-grade marble, and semi-precious stone the ideal choices for lasting beauty and performance.

Quartz remains the most stable option for furniture tops due to near-zero water absorption and high resistance to chemicals and abrasion. Advanced solutions, such as high-resolution stone pattern reproduction, allow designers to achieve luxury aesthetics with controlled performance and supply consistency.

Artificial Stone Is Not “Replacing” Natural Stone: Materials mentioned as “not recommended” for certain uses are not inherently flawed. Each stone type has visual value and specific scenarios where it performs well. Problems arise when materials are used outside their functional limits.

Professional quartz stone suppliers should offer not only material options but also matching solutions, including surface treatments, thickness adjustments, and installation methods that align stone characteristics with real-world demands.

Semi-precious Gemstone Supplier

How to Choose the Right Artificial Stone Supplier

For commercial buyers, selecting a stone supplier is fundamentally about risk management.

1. Brand and Industry Reputation

● Years of operation indicate process maturity and quality stability

● Industry recognition and awards reflect technical capability

● Verified client feedback offers insight into service reliability

Unproven engineered stone suppliers may struggle with consistency, response time, and complex project demands.

2. Production Scale and Capacity

Key factors to verify:

● Standardized production workflows

● Dedicated quality control from raw slab to finished product

● Adequate raw material reserves to avoid mid-project supply interruptions

● Professional warehousing with moisture and impact protection

Small workshops often face supply instability and higher defect rates.

3. Equipment and Processing Capability

Advanced equipment directly affects accuracy and finish quality:

● CNC five-axis cutting machines (±0.5 mm precision)

● Automated polishing lines with uniform gloss levels

● Edge profiling and custom-shape processing capability

Insufficient equipment leads to delays, inconsistent finishes, and limited design execution.

Natural Stone Finished Products

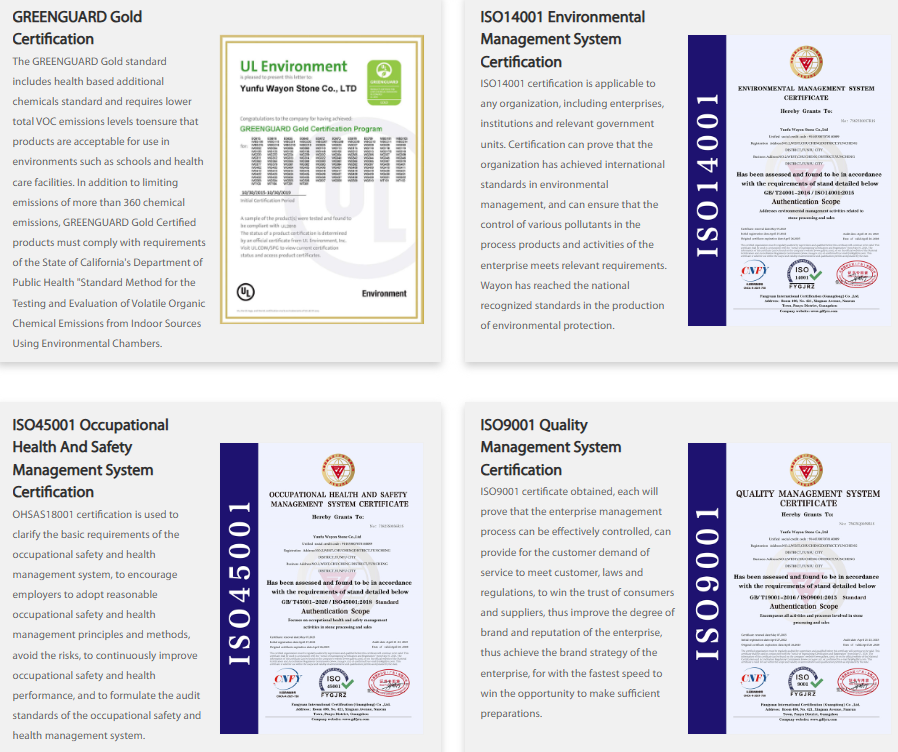

4. Certifications and Compliance

Essential certifications include:

● Product safety standards (CE, GB/T series)

● Quality management systems (ISO 9001)

These ensure physical performance, radiation safety, and consistent production control. Lack of certification increases the risk of rework, rejection, or compliance issues in international projects.

Suppliers with comprehensive certifications are better equipped to meet international compliance requirements. Wayon Stone has obtained GREENGUARD Gold and Indoor Air Quality Certification (UL), NSF (ANSI 51), CE, and ISO 9001 certifications, ensuring product safety, environmental performance, and consistent quality for global projects.

5. Price Evaluation: Looking Beyond Unit Cost

In general, low pricing often signals compromises:

● Inferior raw materials with hidden cracks

● Skipped waterproof or stain-resistant treatments

● Unverified adhesives and pigments

Short-term savings frequently lead to higher maintenance costs, faster material degradation, and potential health risks in interior spaces.

6. Project Case Verification

Reliable suppliers should provide:

● Multiple completed projects, especially similar in scale or function

● Detailed photos showing processing, packaging, and on-site installation

● Consistent visual quality across different projects

Limited or vague case documentation may indicate experience gaps or misrepresentation.

Engineered Stone Factory in China

Logistics, Packaging, and After-Sales Support

Transportation and Packaging

● Proper packaging should match stone characteristics:

● Thick wooden crates and cushioning for large slabs

● Shock-absorbing fillers to prevent movement

● Clear handling labels and lifting instructions

Inadequate packaging increases breakage rates and replacement delays.

After-Sales Service

Strong engineered stone suppliers define:

● Written warranty coverage

● Clear responsibility boundaries

● Fast response times with concrete solutions

Lack of after-sales support often leads to project delays, mismatched replacement materials, and long-term disputes.

Why Artificial Stone Works for Commercial Projects

For hotels, malls, offices, healthcare facilities, and large residential developments, artificial stone and engineered stone offer measurable advantages:

● Predictable performance

● Stable large-volume supply

● Controlled cost over long service life

● Reduced maintenance and downtime

The key lies in pairing the right material with the right application and working with suppliers who understand commercial risk, not just product catalogs.

Wayon has decades of experience in supporting large-scale stone projects, delivering end-to-end artificial stone solutions for commercial, public, and residential developments worldwide. Explore our project portfolio to see how Wayon stone performs across different application sectors.

Wayon Artificial Stone for Apartment

Partnering with a Professional Manufacturer

At Wayon, artificial stone is approached as a system solution rather than a standalone material. From selection and customization to processing, logistics, and post-installation support, each step is designed to reduce uncertainty for project owners, designers, and contractors.

There are no universally “wrong” stones—only mismatched applications. With proper planning and technical support, artificial stone and engineered stone can deliver long-term value, visual consistency, and operational reliability across commercial projects worldwide.

For buyers focused on performance, scalability, and lifecycle cost control, the right artificial stone partner makes all the difference. Contact Wayon today to explore tailored solutions that elevate your projects and ensure lasting results!