Deeply cultivated in the stone industry for more than 40 years, protecting the original beauty of natural marble

Natural Marble

When it comes to natural marble, are you not only tempted by its uniqueness, but also worried about "fragile, cracked, bad transportation"?

Don't worry! Wayon Stone, which has been deeply engaged in the stone field for more than 40 years, has long turned these concerns into "reassuring advantages"!

From rich variety textures, to the detailed process of making stone "resistant to manufacturing", to worry-free whole process service, every step hides the ultimate pursuit of quality.

Variety texture ceiling

From classic to luxury stone

To choose marble, you must first "appear and taste". The variety library accumulated by Wayon Stone over the past 43 years is simply a "treasure house of inspiration" for designers.

Full coverage of classic colors: beige (white Magnolia, White Sand beige, Portuguese beige) is warm and versatile, suitable for creating a warm and high-end feeling; black and white gray (ink cloud gray, Fendi black, Nobel gray) is simple and elegant, suitable for modern and minimalist style;

Luxury stone products are not the same: the Bvlgari black grain has its own nobility, the fine luster of the blue sand seems to hide the starry sky, and the background color of Prada green is high-end, and each one is a "natural limited edition";

The special categories are super eye-catching: the natural hole texture of white caves, yellow caves and Roman caves, and the pure texture of fish belly white and elegant white make the space jump out of mediocrity in an instant.

"More importantly"

The texture of each piece of marble is purely natural, and there is no repetition - to choose Wayon is to choose "exclusive space appearance".

Engineering-grade processing technology

"Resistant" and accurate

The "exquitty" of natural marble is not a problem in the face of Wayon's processing technology at all - in response to the strict needs of engineering scenes, every process is "adaptive to engineering and long-lasting";

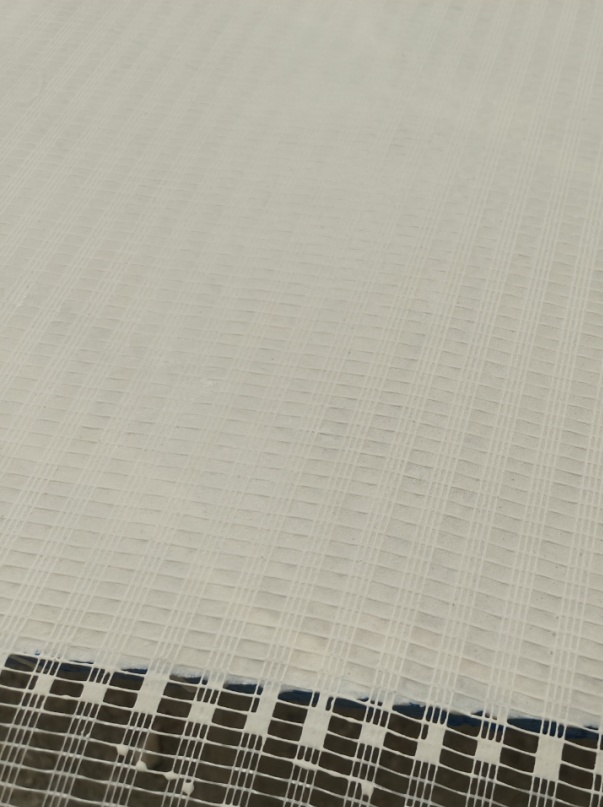

Double reinforcement process

Back mesh reinforcement: conventional wall and floor stone are all treated with back mesh, high-strength fiber mesh firmly locks the internal structure of the stone, the damage rate of transportation installation is 80% lower than that of the industry, and is suitable for large-scale paving of shopping malls, hotel walls and other basic scenes;

Backstring reinforcement: For engineering special-shaped parts (reliefed base), large-size stone (whole wall panel, long-span staircase), customized metal bars are embedded on the back or inside of the stone to form an "invisible internal skeleton", which can effectively disperse the force and prevent deformation and cracking in long-term use. Even high-frequency use scenarios such as transportation hubs can be easily dealt with;

Precision processing ability

Pre-typesetting saves time: Relying on Italy's advanced processing equipment and intelligent system, complete the stone pre-typesetting according to the engineering drawings before delivery, adjust the texture direction and color transition, affix a numbered label to each piece of stone, and install it according to the number on site, so as to avoid the inefficiency of repeated adjustment and greatly improve the construction efficiency;

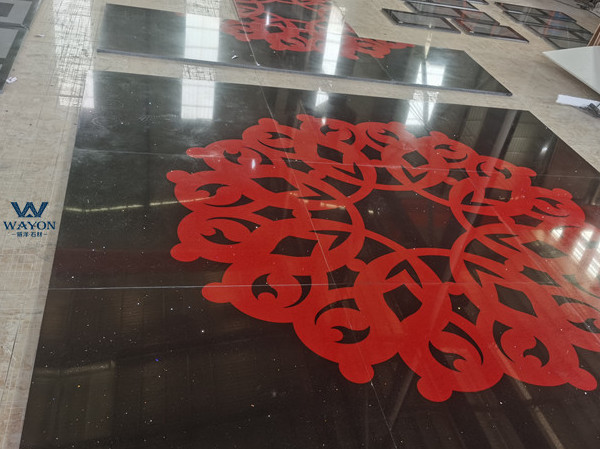

Shape-shaped customization without pressure: from the curved wall and water knife mosaic floor required for the project, to the customized guardrail and countertop, millimeter-level processing is achieved with CNC cutting machine tools and high-precision waterjet machines. As long as there is a design drawing, it can be accurately landed to meet the modeling needs of complex projects;

Full-process engineering services

Professional packaging to prevent damage

Using customized wooden boxes + cushioning fillers, the whole process is moisture-proof, pressure-proof, scratch-proof, and cross-border transportation can also be intact;

Full-process closed-loop service

From project consultation, stone selection, CAD drawing disassembly, pre-setting optimization, to production and processing, dark cracking investigation, quality inspection and packaging, logistics follow-up, to after-sales installation guidance, there is a professional team docking in every link, which not only controls costs but also ensures efficiency.

Benchmark project seal

Domestic and foreign engineering, the strength is obvious.

Guangzhou Baiyun Railway Station

Algeria Airport

Cairo Airport, Egypt

Wayon's full-dimensional advantages have long been verified by many high-end projects.

Domestic cases: the ground stone of Guangzhou Baiyun Station, the wall stone of Zhoushan Green City Hotel, the decorative panel of Zhangjiagang Municipal Government, and the ink cloud gray wall of Macao Yunshun Mall, covering hotels, government, transportation, shopping malls and other diverse scenes;

International case: The stone facilities of Algeria Airport and Cairo Airport in Egypt have been recognized overseas for their stable quality and efficient delivery;

Application form: from the ground, wall, stairs, to table panels and special-shaped decorative parts, the whole form of landing meets the different needs of the project.

High-end stone engineering, it is more reliable to find Wayon

After 43 years of intensive cultivation, Wayon Stone is no longer a simple "stone supplier", but a one-stop partner that can provide "high-quality marble + full-dimensional technical guarantee + worry-free service" for high-end projects.

If your project is looking for a stone solution and leave a message in the comment area "Engineering Consultation", you can get similar project case manuals and exclusive quotation plans~