Finished Stone Products for Architectural Engineering Projects

From large commercial complexes to high-end hotels and residential developments, the demand for reliable, precisely processed stone has grown steadily over the past decades. Clients today are not only looking for beautiful stone surfaces, but also for manufacturers who can provide stable quality, technical support, and real project experience.

Wayon Stone, established in China in 1982, has grown into a global manufacturer of advanced stone materials by consistently focusing on these exact needs. With over forty years of experience, Wayon has built a complete system that covers material production, stone processing, customization, and project-level solutions for architectural engineering worldwide.

Advanced Stone Materials Manufacturer in China

A Long-Term Stone Manufacturer with Global Engineering Experience

Wayon Stone operates four major production and processing bases, with an annual output exceeding 3 million square meters. This scale allows us to handle both standard orders and complex architectural engineering projects without sacrificing consistency.

Key Material Types

- Quartz

- Terrazzo

- Marble & Artificial Marble

- Gemstone

- Cement Stone

- Flexible Stone & Innovative Stone Materials

These materials are widely applied in commercial real estate projects, luxury hotels, home furnishing brands, and public buildings.

Over the years, Wayon has delivered finished stone products and one-stop solutions to clients in more than 80 countries and regions. Rather than acting only as a stone supplier, Wayon supports architectural engineering clients from early-stage material research and development to design optimization and installation guidance, reducing risks on site and improving overall construction efficiency.

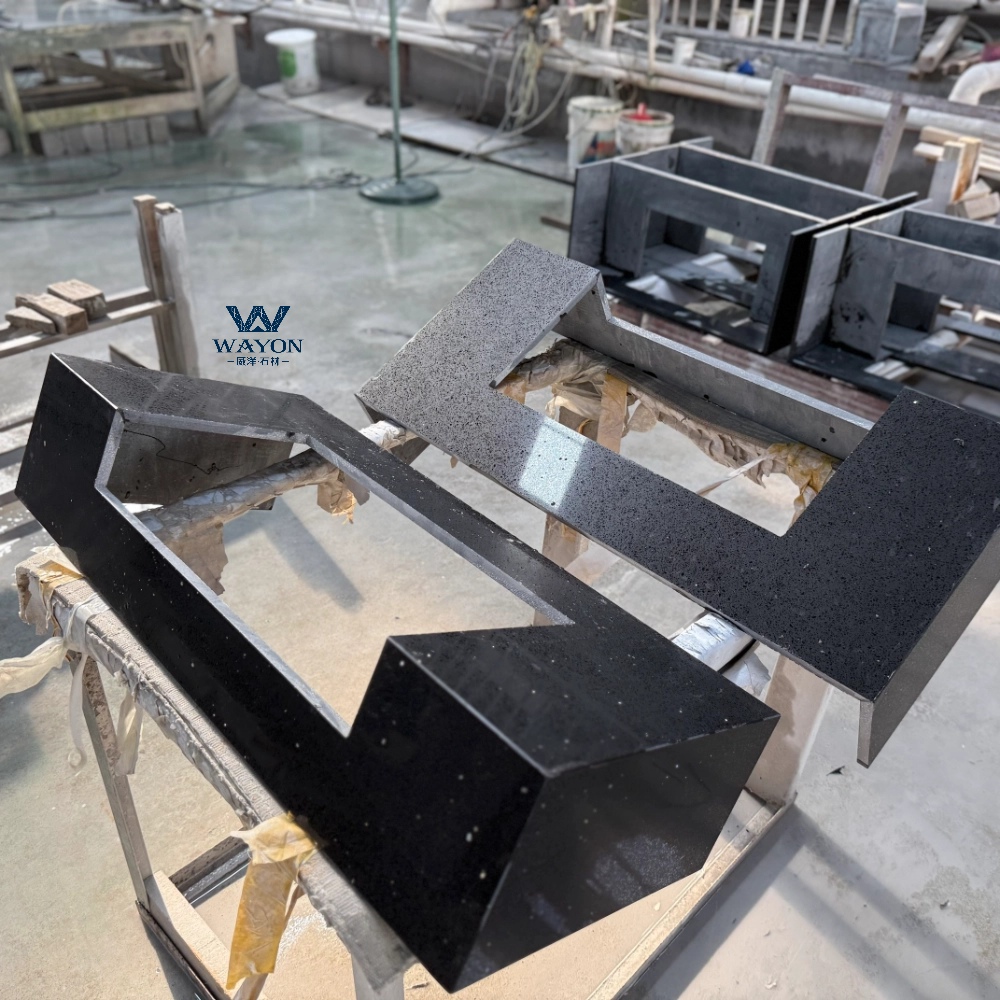

Finished Stone Products Designed for Architectural Engineering

Architectural engineering projects demand more than raw slabs. They require finished stone products that are cut, edged, drilled, assembled, and packaged to fit directly into construction workflows. Wayon Stone focuses heavily on this processing stage, where design intent becomes a physical product.

1. Kitchen Countertops for Engineering and Residential Projects

We specialize in kitchen countertops suitable for residential developments and commercial projects such as serviced apartments and hotels.

Product Features:

- American standard countertops and engineering customized countertops

- Kitchen islands

- Edge profiles: Bullnose, 45° miter, DuPont, Ogee, and more

- Materials: Quartz stone, granite, marble

Precision cutting and edge finishing ensure perfect alignment with cabinets and appliances, especially critical for large-scale projects.

2. Bathroom Vanity Tops with Functional Details

Bathroom vanity tops may seem small, but in engineering projects they are often used in large quantities, and any inconsistency can be noticeable. Wayon Stone provides:

- Cutting holes for under- or above-counter basins

- Faucet holes

- Hang-down edges (2–20 cm)

- Integrated backsplashes

- One-piece stone basins, column basins, borderless wash basins

- Fully customized designs

These solutions are ideal for hotels, serviced residences, and premium apartments where durability and maintenance are essential.

3. Furniture Table Tops for Commercial and Public Spaces

Finished stone furniture table tops are increasingly popular in hotel lobbies, restaurants, office meeting rooms, and commercial lounges. Wayon can process table tops for coffee tables, dining tables, hot pot tables, negotiation tables, conference tables, and outdoor rest areas. Customization options:

- Shapes: Circular, elliptical, arc-shaped, polygonal, fully custom

- Edge treatments: Thickened edges, thin edges, half bullnose, straight edges

4. Cut-to-Size Stone for Walls and Flooring

For wall and floor applications, Wayon Stone provides cut-to-size stone tiles tailored for architectural engineering projects. Standard sizes such as 600×600 mm, 600×1200 mm, and 800×800 mm are available, along with smaller sample sizes like 100×100 mm or 150×300 mm.

Wayon also processes mosaic puzzle stone and water jet parquet for background walls and feature floors. These elements are often used in hotel lobbies, commercial atriums, and high-end residential entrances, where visual impact is important but precision is non-negotiable.

5. Customized Stone Designs That Match Architectural Concepts

Customization is one of the most demanding parts of architectural engineering, and also one of the most valuable. Wayon Stone supports customized designs, including special styles, brand logos, and unique patterns. Customization is not limited to product shapes, but extends to wall and floor mosaic design as well. New designs are tested and refined during production to ensure feasibility before full-scale application.

Advanced Stone Processing Facilities That Support Large Projects

Behind every finished stone product is a processing system that determines quality and efficiency. Wayon Stone Processing Center covers 6,500 square meters and is equipped with a full set of professional machinery.

Key Equipment

- 12 Taiwanese bridge cutting machines

- Italian five-axis phototypesetting automatic suction cup bridge cutting machine

- Italian and Taiwanese automatic edge grinding machines

- Cabinet countertop assembly line

- 3 CNC drilling machines

- 5 high-quality sample machines

- 4+8-head molding system

The advanced equipment setup allows us to handle complex cuts, precise edge treatments, and consistent mass production. For architectural engineering projects with tight schedules, this processing capacity directly translates into shorter lead times and fewer on-site issues.

Pre-Fabricated Stone Solutions for Efficient Construction

Modern architectural projects increasingly favor pre-fabricated stone solutions, which save time and reduce on-site work.

- Faster installation

- Reduced on-site cutting and wet work

- Improved safety

- Consistent quality and durability

Pre-fabricated stone and solutions are especially suitable for commercial buildings, hotels, and large residential developments where speed and quality control are both critical.

Packaging and Logistics for Global Engineering Projects

Stone is heavy and fragile, so proper packaging is critical. You can choose:

- Cardboard boxes

- Wooden boxes

- Wooden pallets

- A-frame packaging

- Wooden clip packaging

Wayon Stone offers packaging solutions tailored to client requirements and project conditions. This flexibility ensures that finished stone products arrive on site in good condition, ready for installation.

Serving Architectural Engineering Clients Worldwide

Wayon Stone has worked with a wide range of clients, from commercial real estate developers to high-end hotel operators and engineering contractors. Our ability to provide one-stop stone solutions, covering material selection, processing, and installation guidance, makes us a reliable partner for international architectural engineering projects.

By combining large-scale production, advanced processing, and practical project experience, Wayon continues to support complex construction projects across different markets.

Conclusion: Why Architectural Engineering Projects Choose Wayon Stone?

Finished stone products play a critical role in architectural engineering projects, affecting not only aesthetics but also construction efficiency and long-term performance. Wayon Stone brings together:

- Decades of manufacturing experience

- Advanced stone processing capabilities

- Practical project knowledge

From kitchen countertops and bathroom vanity tops to fully customized stone designs, Wayon delivers solutions that are practical, durable, and visually consistent. With reliable packaging, global logistics support, and professional technical guidance, Wayon Stone is a partner that architects and engineers can trust.

Contact Wayon Stone today to discuss your architectural engineering project and explore stone solutions that meet your design and construction goals.