How to Customize Quartz Stone for Hotel Engineering Projects?

From lobby walls to bathroom vanity tops, from guestroom countertops to decorative features, the way quartz stone is customized directly affects construction efficiency and final results.

For hotel developers and contractors, choosing the right quartz stone supplier is not only about color or price. It is about manufacturing capability, stable supply, precision fabrication, and how well the material adapts to different hotel spaces.

This article explains how quartz stone can be customized for hotel engineering projects from a practical point of view, based on real application scenarios. It also shares how Wayon approaches quartz stone manufacturing and customization for hotels worldwide.

Quartz Stone Manufacturer in China

Why Custom Quartz Stone Makes Sense for Hotels?

Hotels demand more than visual appeal. They need materials that can handle daily use while maintaining their original look. Quartz stone offers:

- High-density structure resisting scratches and stains

- Stable color and texture over time

- Easy maintenance for hotel operations

- Design flexibility through customization

Custom quartz stone helps hotels avoid these problems from the beginning. When customized correctly, quartz stone becomes both a design element and a practical engineering solution.

1. Customization Improves Construction Efficiency

When slab sizes, thickness, and cutouts are planned according to actual site conditions, on-site adjustments are reduced. For large hotel projects, this directly affects labor costs and overall coordination.

2. Custom Quartz Stone Supports Visual Consistency Across Large Areas

Hotels rely on a unified design language, especially in public spaces like lobbies, corridors, and restaurants. Factory-controlled production ensures color stability and vein continuity from batch to batch, something difficult to achieve with mixed or standard materials.

3. Long-Term Maintenance Becomes Easier

Quartz stone’s high-density structure resists scratches, stains, and moisture. When edges, joints, and surfaces are customized and fabricated correctly, daily cleaning is simpler.

4. Customization Gives Designers More Freedom Without Sacrificing Performance

Curved countertops, special-shaped wall panels, and integrated vanity solutions allow hotels to create distinctive spaces while still using a durable and practical material. For hotels that value durability and consistency, custom quartz stone is a practical and cost-effective choice.

Understanding Hotel Engineering Needs Before Customization

Hotel projects are different from residential or small commercial jobs. The scale is larger, timelines are tighter, and consistency matters more than anything else. Before customization begins, several key factors are usually considered:

- Large-area application with visual consistency

- High frequency use and strict durability requirements

- Complex layouts with curved or irregular designs

- Compliance with safety, environmental, and certification standards

Quartz stone fits these needs well, but only when the product is engineered and customized with hotel usage in mind.

Quartz Stone Applications in Hotel Projects

In hotel projects, quartz stone is often used in multiple areas of the same building, requiring consistent performance and appearance, which makes customization a practical necessity rather than an option.

1. Hotel Countertops and Reception Desks

Hotel countertops are among the most frequently used surfaces. They appear in reception desks, bar counters, restaurant service areas, and business lounges. For these areas, quartz stone customization focuses on:

- Slab size to reduce joints

- Edge profiles suitable for public use

- Scratch and stain resistance for long-term maintenance

Wayon quartz stone slabs are available in common large sizes such as 3200x1600mm and 3000x1400mm, helping reduce visible seams in large counters. Thickness options from 12mm to 30mm allow designers to balance visual weight and structural needs.

Custom edge processing and CNC cutting ensure that undermount sinks, cable openings, and irregular edges match the original design drawings accurately.

2. Bathroom Vanity Tops and Washbasin Panels

Bathrooms are one of the most demanding areas in hotel projects. Moisture, cleaning chemicals, and daily use all test material performance. Quartz stone is widely used for:

- Bathroom vanity tops

- Integrated washbasin panels

- Wall panels around wet areas

With water absorption ≤0.01%, Wayon quartz stone performs well in humid environments. Its dense structure helps prevent stains and makes daily cleaning easier for hotel operations teams.

Customized washbasin panels and sink cutouts are fabricated with ±0.5mm CNC precision, ensuring smooth installation and clean finishing on site.

3. Walls and Decorative Cladding

Quartz stone is no longer limited to horizontal surfaces. In many modern hotel designs, it is used on:

- Lobby feature walls

- Elevator halls

- Commercial display walls

- Public area decorative panels

For wall applications, consistency in color, vein pattern, and slab thickness becomes critical. Wayon’s production process includes material screening based on vein distribution and density, helping maintain a uniform visual effect across large wall areas.

Custom-cut wall panels and irregular shapes allow designers to break away from flat, standard layouts and create visual focal points.

4. Flooring for Hotel Apartments and Public Areas

While quartz stone is not always the first choice for flooring, it is increasingly used in:

- Hotel apartments

- Boutique hotels

- Selected public areas with controlled traffic

With Mohs hardness of 6–7, quartz stone offers good wear resistance. Combined with precise cutting and polishing, it provides a clean and modern flooring solution that is easy to maintain.

Customization Dimensions That Matter in Hotel Projects

After defining the application areas, customization becomes the next practical focus. Factors like size, thickness, color control, and processing accuracy directly affect installation efficiency and overall project results.

1. Slab Sizes and Thickness Options

Hotel engineering projects rarely rely on standard sizes only. Different spaces require different dimensions. Wayon offers:

- Standard large slabs for mass application

- Custom slab sizes for special layouts

- Thickness options from 12mm to 30mm

This flexibility helps reduce on-site cutting, improve installation efficiency, and lower material waste.

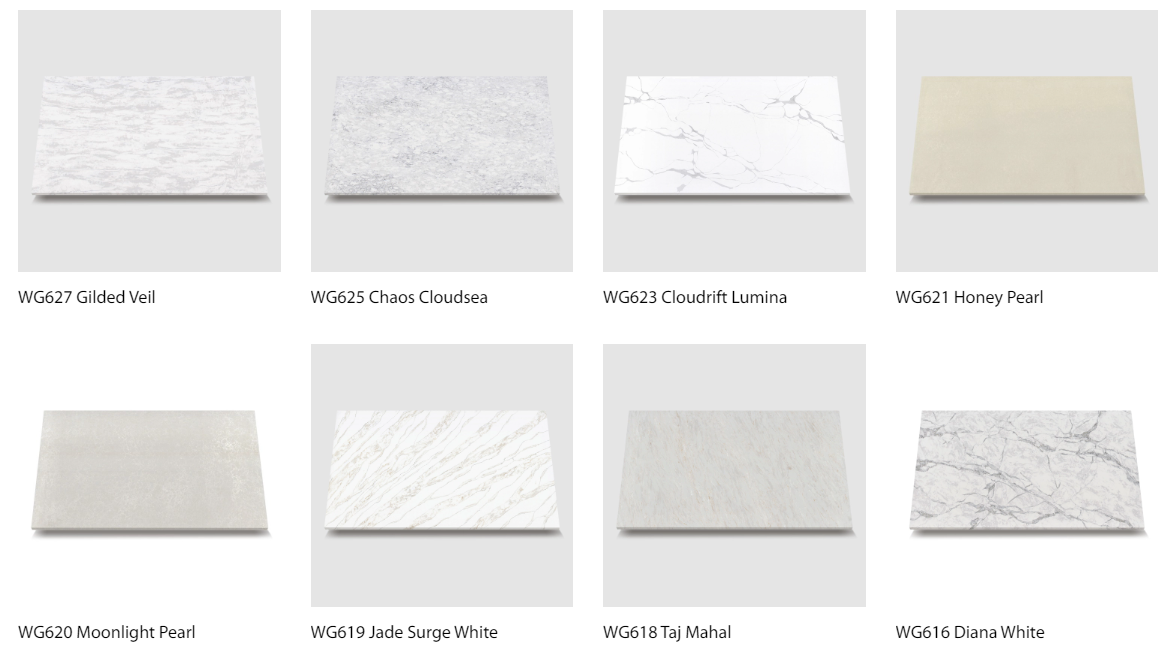

2. Colors, Textures, and Design Styles

Hotels rely heavily on atmosphere. Quartz stone plays a quiet but important role in shaping it. Wayon quartz stone offers a wide range of:

- Neutral base colors for modern and minimalist hotels

- Natural stone-inspired textures for classic and luxury projects

- Custom-developed textures for unique design concepts

The design team of Wayon continues to develop new base colors and surface patterns, allowing quartz stone to match different interior styles, from modern urban hotels to European-inspired luxury spaces.

3. Irregular Shapes and Curved Designs

Standard rectangular slabs cannot meet all hotel design needs. We break away from standardization by offering:

- Curved countertops

- Irregular wall panels

- Special-shaped railing and decorative components

Factory-level CNC fabrication ensures curved lines and complex shapes are accurately reproduced from design drawings to finished products, helping designers fully express creativity without being limited by material constraints.

What Makes Wayon Reliable for Large Hotel Projects?

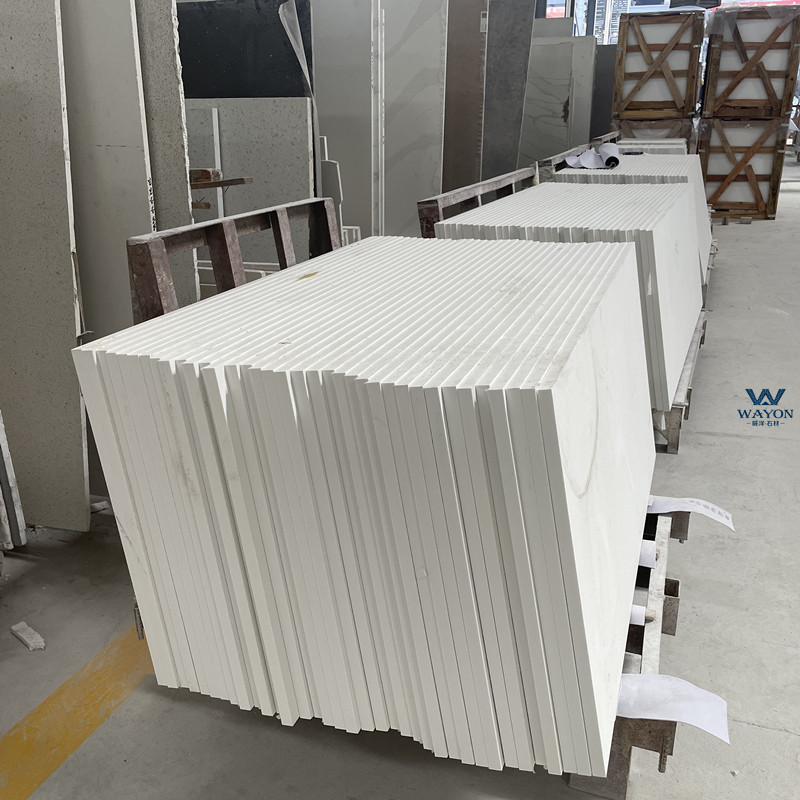

Customization only works when supported by real manufacturing capacity. Wayon Stone operates a solid cross-regional production layout. The Yunfu production base, covering 20,000 square meters, is equipped with:

- 4 automatic pressing production lines

- 1 independently developed block-type production line

- 2 polishing lines imported from Italy

With an annual output of over 1.2 million square meters of artificial quartz stone, Wayon is able to support both large hotel engineering orders and urgent project timelines. Standardized inventory combined with large-scale production capacity allows fast response for urgent orders and stable delivery for bulk hotel projects.

How We Achieve Accurate Cutting and Complex Shapes?

From raw material to finished product, we follow a full fabrication loop:

- CNC cutting for precise sink cutouts and edges

- Compatibility with quartz, marble, terrazzo, and granite

- Smooth finishing with invisible joints and preserved veining

- Full-process inspection from slab selection to final packaging

Pre-applied stain and scratch-resistant treatments help enhance durability before materials even leave the factory. This combination of custom fabrication and stable supply helps contractors reduce installation risks and control overall project costs.

Wayon Stone Processing Factory

Safety, Certification, and Long-Term Reliability

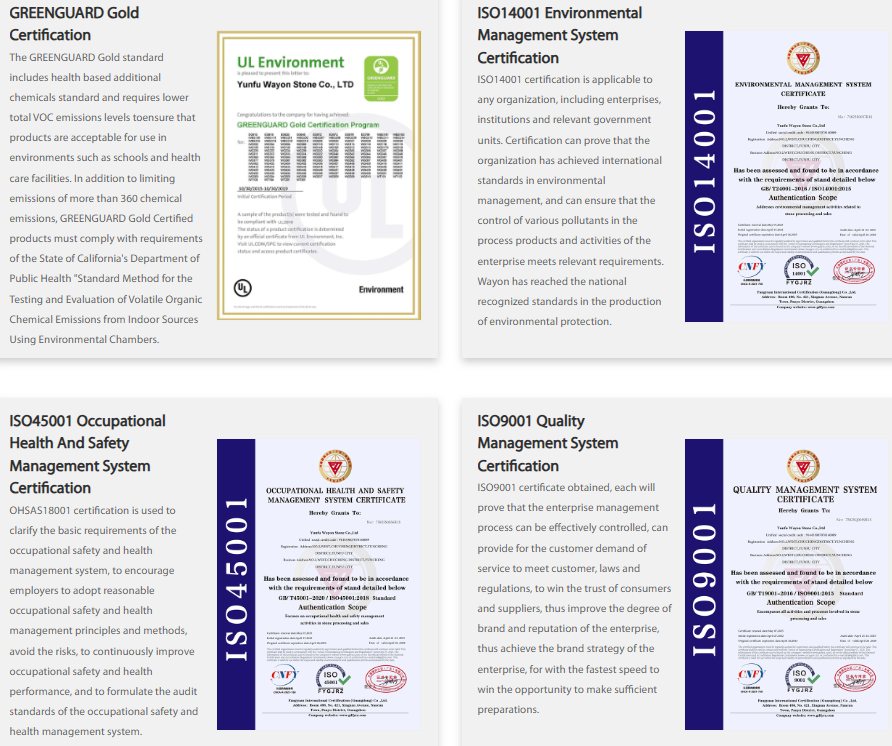

For hotel projects, safety and compliance are not optional. Wayon quartz stone meets international standards and holds certifications including:

Greenguard Gold & Greenguard Indoor Air Quality Certification (UL)

- NSF Certification (ANSI 51)

- CE Safety Certification (SGS)

- ISO9001 Quality, Environment, and Occupational Health Management System

For hotel developers and contractors, these certifications and quality systems reduce risk during approval, installation, and operation. Combined with proven export experience and stable manufacturing, Wayon provides a reliable quartz stone solution for long-term hotel projects worldwide.

Conclusion: Partnering with Wayon for Hotel Quartz Stone Projects

Customizing quartz stone for hotel engineering projects is not about choosing a pattern from a catalog. It is about understanding how the material will be used, fabricated, installed, and maintained over many years.

With strong manufacturing foundations, flexible customization capabilities, certified safety standards, and precise fabrication, Wayon supports hotel developers, designers, and contractors from concept to completion.

If you are planning a hotel project and looking for a reliable quartz stone manufacturer that understands engineering realities, Wayon is ready to help turn your design ideas into durable, high-quality stone solutions.