Why Inorganic Terrazzo Flooring Is Ideal for High-Traffic Commercial Spaces

Nowadays, modern commercial projects place far higher expectations on flooring materials than before. Whether it’s a mall with nonstop foot traffic, a hospital that requires strict air-quality control, or a transportation hub that needs a surface that can withstand trolleys, humidity, and cleaning chemicals—materials must stay stable, look consistent, and offer predictable performance year after year.

This shift in project demand explains why inorganic terrazzo has rapidly become a preferred choice among architects, contractors, and terrazzo solution buyers. Compared with many conventional terrazzo floor products on the market, pure inorganic terrazzo tiles offer better durability, stronger environmental credentials, and longer lifecycle value.

Among the professional terrazzo suppliers in this category, Wayon, a long-established inorganic terrazzo company and one of the trusted terrazzo manufacturers in China, has pushed the category forward with its high-performance inorganic terrazzo slabs used in commercial spaces around the world.

Below is a detailed look at how inorganic terrazzo compares with other terrazzo options—and why Wayon terrazzo tiles align particularly well with high-traffic project requirements.

Inorganic Terrazzo Company in China

1. Why Inorganic Terrazzo Is Rising in High-Traffic Commercial Environments

High-traffic commercial environments—such as malls, airports, hospitals, schools, and mixed-use complexes—place extreme demands on flooring. Traditional cement terrazzo and resin-based systems often struggle with abrasion, yellowing, moisture issues, and maintenance costs once the space enters full operation.

Key pain points across commercial scenarios include:

- Continuous abrasion from foot traffic, trolleys, and carts

- Heavy rolling loads in airports and transit hubs

- Strict hygiene and zero-VOC requirements in healthcare

- Color stability & non-combustibility required for public buildings

- Moisture, chemical exposure, and frequent cleaning in hospitality and retail

- UV and weather resistance needed for semi-outdoor areas

These rising performance demands are driving developers to upgrade from traditional or organic terrazzo to inorganic terrazzo, which offers:

- Higher density and wear resistance

- Zero-organic, low-VOC composition

- Better moisture, stain, and UV resistance

- Long-term color and structural stability

This is why inorganic terrazzo—especially solutions engineered by Wayon, a leading inorganic terrazzo manufacturer in China—is becoming the preferred flooring for modern high-traffic commercial projects.

Wayon Terrazzo Tile Flooring Solutions

2. Wayon Inorganic Terrazzo vs. Traditional Terrazzo: A Comprehensive Comparison

Traditional terrazzo, whether cement-based or resin-modified, has served commercial spaces for decades. It delivers a classic look, but as project scales grow and floor performance requirements tighten, many developers are finding that older formulations cannot always keep up with today’s traffic intensity, hygiene standards, or long-term maintenance expectations.

Wayon’s inorganic terrazzo takes a different approach. Instead of relying on binders that react to moisture, UV, or chemical exposure, the material is engineered for stability from the start. This results in a slab that maintains density, color consistency, and structural strength even under continuous use.

The comparison below highlights how Wayon inorganic terrazzo differs from traditional terrazzo systems in the areas that matter most to modern commercial projects—durability, installation efficiency, environmental safety, and lifecycle performance.

|

Test Item |

Unit |

Traditional Terrazzo |

Wayon Inorganic Terrazzo |

|

Water Absorption |

% |

≥ 3 |

0.19–0.53 |

|

Moh’s Hardness |

grade |

3 |

4–6 |

|

Density |

g/cm³ |

< 2.3 |

2.37–2.49 |

|

Compressive Strength |

MPa |

< 90 |

101–123 |

|

Flexural Strength (Dry) |

MPa |

< 8 |

12.2–14.5 |

|

Gloss |

– |

< 30 |

49.3–63 |

|

Radioactivity |

– |

Iᵣₐ < 0.1 Iᵧ < 0.1 |

Iᵣₐ < 0.1 Iᵧ < 0.1 |

|

Pore-Free |

– |

● |

●●●●● |

|

Processing Difficulty |

– |

Mostly cast-in-place with no further processing |

Excellent, seamless joints, 45° miter joints |

|

Chemical Resistance |

– |

● |

●●●●● |

|

Wear Resistance |

– |

●●● |

●●●●● |

|

Freeze-Resistant |

– |

● |

●●●●● |

|

Application Area |

– |

Indoor and outdoor floor and wall surfaces |

Indoor and outdoor floors and walls, bathrooms, kitchens, etc. |

|

After-Sales |

– |

Prone to cracking, with pores |

Resistant to warping, discoloration, cracking, and pore-free |

|

Construction |

– |

Requires on-site wet polishing, potentially causing water pollution |

Direct install with cement-sand mix or tile adhesive, no water pollution |

|

Conservation |

– |

Long curing time, extended construction period |

No curing needed; fast installation |

|

Waterproof |

– |

Requires self-leveling and waterproof layers, increasing cost |

No waterproofing needed during installation, reducing cost |

|

Quality |

– |

Manually mixed without large-tonnage pressing; uneven distribution reduces density, leading to pores and cracking |

High-density achieved through vacuum and large-tonnage pressing, with precise mixing and uniform material distribution; consistent color and texture |

|

Surface Treatment |

– |

Cast terrazzo requires secondary surface treatment for stain resistance |

High gloss achieved with physical polishing only, no secondary surface treatment required |

3. Wayon Inorganic Terrazzo vs Organic Terrazzo: Key Advantages

Many people assume all terrazzo is alike. In reality, the industry distinguishes between organic terrazzo and inorganic terrazzo, and this distinction directly affects a project’s durability, performance, and environmental profile.

1) True Inorganic Composition

Organic Terrazzo (or “semi-inorganic” systems)

Often uses cement as the base binder but includes water-based resins or organic additives. Problems tend to appear after months or years of use:

- Potential VOC release

- Cracking and crazing due to resin aging

- Discoloration or fading under UV exposure

- Surface powdering

- Higher water absorption leading to efflorescence

- Weaker performance in hospitals, schools, and highly regulated environments

Wayon Pure Inorganic Terrazzo

Many products marketed as “inorganic terrazzo” still contain a portion of resin. Wayon Terrazzo applied a completely resin-free formula: self-developed cement blend + proprietary inorganic powder + natural stone aggregates. No glue, no resin, no organic binders, delivering high crystallization strength and long-term stability even in high-traffic spaces.

Moreover, independent testing reports confirm full compliance with national standards and suitability for medical spaces requiring superior indoor air quality. For developers pursuing LEED certification or aiming for higher environmental ratings, Wayon Terrazzo is an ideal choice.

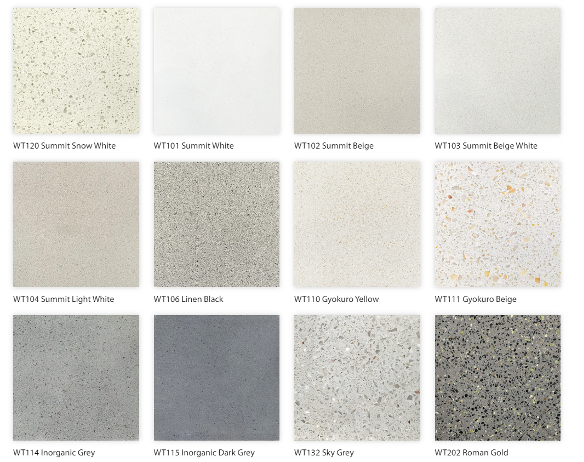

2) Technical Chart: Organic vs. Inorganic Terrazzo

|

Performance |

Organic Terrazzo |

Wayon Inorganic Terrazzo |

|

|

Mohs Hardness |

~3 (susceptible to scratching) |

4–6 (high wear resistance) |

|

|

Density |

<2.3 g/cm³ (porous, loose structure) |

2.36–2.57 g/cm³ (dense, compact) |

|

|

Water Absorption |

≥3% (prone to efflorescence and debonding) |

0.08–2.7% (low absorption, anti-efflorescence) |

|

|

Compressive Strength |

Low (fine processing increases cracking risk) |

High (supports brush-hammered & 45° edge processing) |

|

|

Combustibility |

Combustible (contains resin, easily flammable) |

Non-combustible (resin-free, suitable for flame-treated surfaces) |

|

For buyers, especially those sourcing from China terrazzo slab factories or comparing different terrazzo manufacturers, the technical differences above often determine long-term maintenance cost and overall project risk.

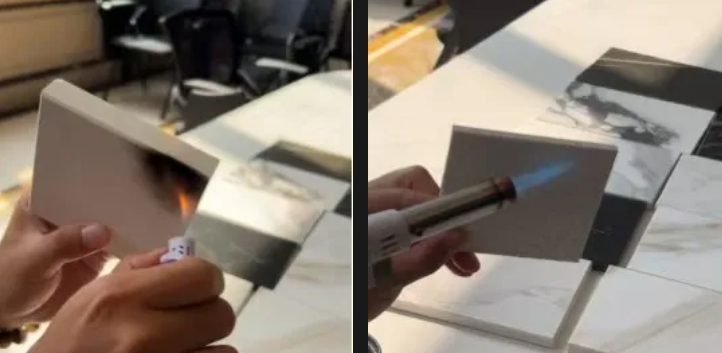

3)How to Identify Real Inorganic Terrazzo

Some terrazzo suppliers market “inorganic” terrazzo that actually contains small amounts of resin. A simple fire test can quickly distinguish genuine inorganic terrazzo from resin-containing imitations.

Required Tools:

- A butane lighter or butane flame gun.

- Avoid kerosene lighters, which can leave carbon residue and produce misleading results.

Test Procedure:

- Select a corner or edge of the terrazzo to avoid affecting the appearance.

- Hold the flame 2–3 cm from the terrazzo surface for 3–5 seconds.

Expected Observations:

- Real Inorganic Terrazzo (Wayon): slight grain popping, similar to a flame-treated stone surface; no smoke or odor; surface remains clean; non-combustible.

- Fake Inorganic Terrazzo (resin-added): black smoke with a burning plastic odor; surface may melt or wrinkle; combustible.

Post-Test Check:

Wipe the surface with a dry cloth. Genuine inorganic terrazzo leaves no residue, whereas fake samples leave black carbon marks.

This simple test provides an effective way for buyers to verify the authenticity of terrazzo slabs, helping to avoid costly mistakes.

Wayon Inorganic Terrazzo Vs Organic Terrazzo

4) Performance Strength for Demanding Applications

Wayon inorganic terrazzo is manufactured using high-frequency, high-pressure vibration compaction, producing dense slabs with excellent structural integrity. This material structure translates into superior performance across a variety of high-demand commercial and public environments:

Hospitals – Clean, Stable, VOC-Free

The zero-organic formula ensures no emissions or odor, fully complying with strict healthcare standards. Surfaces remain smooth and easy to disinfect for long-term hygiene compliance.

Swimming Facilities – Anti-Efflorescence

With a low water absorption rate of 0.19–0.53%, Wayon terrazzo minimizes whitening, blistering, and moisture-related damage, making it ideal for wet-area floors.

Aquariums and Museums – Long-Term Color Stability

Mineral pigments maintain consistent color even in humid, low-light, or high-visitor environments, ensuring aesthetic longevity.

Shopping Malls and High-Footfall Spaces – Impact and Abrasion Resistant

With Mohs hardness up to Grade 5, the surface resists scratches from strollers, carts, heels, and rolling loads. In high-traffic exhibition or retail spaces, the high hardness ensures the floor remains intact and reduces long-term maintenance costs.

Outdoor Plazas, Kitchens, and Industrial Areas – Fire, Freeze, and UV Resistant

Natural inorganic components withstand extreme temperatures, resist deformation, and maintain color stability under sunlight. This makes Wayon terrazzo suitable for outdoor plazas exposed to cold, high-temperature kitchens, chemical workshops, or other extreme indoor and outdoor environments.

Wayon inorganic terrazzo’s combination of hardness, low water absorption, fire and freeze resistance, and UV stability ensures durability, aesthetic consistency, and minimal maintenance across demanding commercial and public applications.

China Terrazzo Slabs for Flooring

4. Tips for Selecting, Installing, and Maintaining Inorganic Terrazzo

1) Key Considerations When Selecting Terrazzo Tiles

Avoid “short production cycle” terrazzo

Cement is the core inorganic binder in true inorganic terrazzo, and its hydration process requires a stable curing period—typically not less than 10 days. This reaction cannot be accelerated without compromising the internal structure of the slab.

If a terrazzo supplier advertises “7–15 days delivery” or unusually fast production, it often means the material has not been fully cured. Incomplete hydration may leave hidden voids or microcracks inside the slab. These issues may not be visible during installation, but over the following months, they can increase the chance of efflorescence, hollowing, or surface cracking, leading to higher maintenance needs or even costly replacement work.

Be cautious of unusually high flexural strength claims

For pure inorganic terrazzo, the typical and compliant flexural strength range is ≥8 MPa, aligned with the GB/T 35164-2017 standard. When a product claims values as high as 20 MPa or above, it often indicates the use of resin, unsaturated polyester, or other organic binders to boost short-term strength.

While such slabs may appear strong initially, the added organic content can reduce heat resistance, making large floor areas more prone to deformation or surface issues under high temperatures. Their UV stability is also weaker, which may lead to discoloration or fading in outdoor or sun-exposed environments.

During dry cutting, pure inorganic terrazzo typically produces no unusual smell, whereas resin-modified products may release chemical or acidic odors, providing an immediate indication of organic additives.

Top Inorganic Terrazzo Factory In China

2) Installation & Maintenance

Back-glue is essential for large areas

For large commercial surfaces, applying back-glue is a key step. It creates a dense waterproof layer on the underside of the slab, helping block moisture from the substrate and reducing stress caused by humidity differences. This lowers the likelihood of cracking or efflorescence over time.

Wayon provides a dedicated terrazzo installation manual with detailed procedures, tool lists, and on-site precautions for contractors.

Fast Installation

Since Wayon inorganic terrazzo does not require on-site casting, installation is straightforward. The terrazzo slabs can typically be installed and reach initial curing in around 24 hours, allowing project teams to shorten schedules significantly compared to traditional terrazzo flooring.

Use the Correct Thickness

Selecting the appropriate thickness ensures both performance and cost efficiency. For most projects, 20 mm is recommended for indoor applications, while 25 mm is preferred for outdoor areas to accommodate higher loads and environmental exposure. This approach delivers reliable durability without unnecessary material expense.

Easy Long-term Care

Daily maintenance is simple—regular cleaning with water or a damp cloth is usually enough to keep the surface clean. With no organic components, the material is less prone to efflorescence, surface cracking, or delamination, helping reduce repair frequency and long-term operating costs.

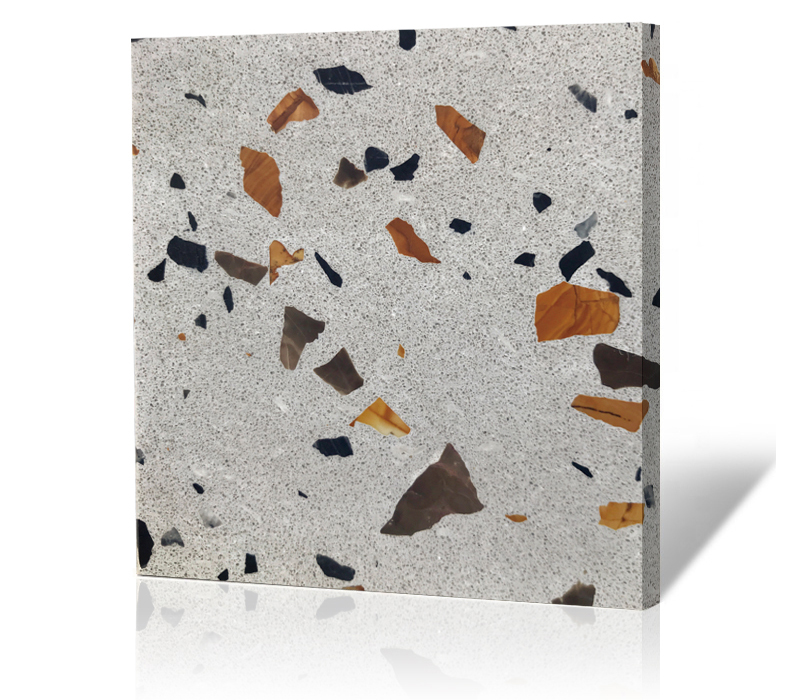

5. Wayon High-Performance Inorganic Terrazzo

Wayon’s high-performance inorganic terrazzo contains up to 60% natural quartz-based aggregates, bound with proprietary, environment-friendly inorganic adhesives and mineral pigments. No resin, glue, or other organic binders are used. It is formed by high-frequency, high-pressure vibration molding, giving it superior compactness, durability, and surface integrity.

Material Characteristics

- High Mohs hardness and density: Provides excellent wear resistance, scratch resistance, and long-lasting durability.

- Class A fire rating, non-combustible: Raw materials are entirely non-flammable; the product resists deformation under high temperatures and does not release toxic smoke.

- UV resistant: Ideal for outdoor plazas, facades, and other exterior applications; retains color without fading.

- Low water absorption: Minimizes efflorescence, making it suitable for indoor and outdoor walls, floors, kitchen countertops, and bathroom surfaces.

- Chemical, corrosion, and freeze resistance: Suitable for harsh environments, including exposure to acids, salts, and extreme weather.

- Consistent long-term gloss and surface integrity: Natural oiliness and high polish retention keep surfaces visually striking for years.

- Customizable aesthetics: Colors, aggregate ratios, and textures can be tailored to design needs; supports unique patterns, green design, and sustainable applications.

- High compressive and flexural strength: Compatible with specialized surface treatments such as flamed finishes and 45° edge fabrication.

Wayon Iwayama Grey Terrazzo Specifications

Available Sizes

Slabs:

- 2400×1600 mm

- 2400×1800 mm

- 2700×1800 mm (max)

Cut-to-size:

- 600×600 mm

- 800×800 mm

- Custom sizes available

Finishes:

Polished / Honed / Flamed / Brush-Hammered / Water-Jet

Thickness:

15 mm / 18 mm (standard) / 20 mm / 30 mm

Application Fields

Thanks to its durability, fire resistance, gloss retention, and low absorption, Wayon inorganic terrazzo is widely used for:

- Shopping malls and commercial complexes

- Flagship retail stores

- Restaurants and hospitality facilities

- Municipal and public architecture

- Indoor & outdoor walls and flooring

- Kitchen and bathroom surfaces

It has also become popular among international buyers sourcing premium China terrazzo slabs for high-spec projects.

6. Project Case: Wayon Inorganic Terrazzo for Moer Apartment in Beijing

The WT210 Iwayama Grey terrazzo from Wayon was selected for the Moer Apartment. Its soft grey base and natural stone aggregate pattern create a calm, elegant visual field. The refined texture appears consistent across both flooring and wall applications, adding cohesion to the architectural space.

WT210 Iwayama Grey terrazzo tiles performed well in both indoor and outdoor conditions, demonstrating:

- High slip resistance

- Strong surface hardness

- Long-term color stability

- A clean, natural stone-like texture that suits modern commercial design

This project exemplifies how Wayon supports clients looking for reliable inorganic terrazzo supply backed by processing precision and stable product performance.

6. Final Word: Why Inorganic Terrazzo Is the Future of Commercial Flooring

For commercial developers, designers, and engineering teams, choosing the right terrazzo is not just a matter of picking a design—it’s choosing a system capable of preventing hidden risks, long-term failures, and avoidable maintenance costs.

Wayon has invested years into developing high-performance inorganic terrazzo, focusing on material science, environmental compliance, and consistent supply capability. From raw materials to production standards, every part of its system is designed to withstand the demands of high-traffic public environments.

Backed by complete third-party test reports and an open verification process, Wayon offers clarity and confidence to buyers who need trustworthy performance—not marketing claims.

For commercial projects that demand durability, stability, and long-term value, inorganic terrazzo is no longer an alternative—it’s the material that meets modern expectations, and Wayon stands among the most reliable options in the market. Discover how Wayon inorganic terrazzo can support your next project: Contact Wayon Today!

Custom Terrazzo For Commercial Projects

Frequently Asked Questions (FAQs) about Terrazzo

What is the difference between inorganic and organic terrazzo?

Inorganic terrazzo uses cement or proprietary inorganic binders without resin or organic additives, making it VOC-free, fire-resistant, and highly durable. Organic terrazzo typically contains resin, which can emit VOCs, be less heat-resistant, and wear faster in high-traffic areas.

Why choose inorganic terrazzo for high-traffic commercial spaces?

Inorganic terrazzo offers high hardness, low water absorption, and resistance to abrasion, chemicals, UV, and temperature extremes, making it ideal for malls, airports, hospitals, and industrial facilities.

How long does inorganic terrazzo take to cure?

Cement-based inorganic terrazzo requires a minimum hydration period of 10 days to achieve optimal structural integrity. Rushing production may cause internal voids or microcracks.

Can inorganic terrazzo be used outdoors?

Yes. Its UV resistance, low water absorption, and freeze-thaw durability make it suitable for outdoor plazas, facades, walkways, and northern climates with extreme temperature variations.

What thickness should I choose for terrazzo slabs or tiles?

Typical thicknesses are 15 mm, 18 mm (standard), 20 mm, and 30 mm, depending on location, load, and installation type. Indoor areas usually use 18–20 mm, while outdoor or heavy-load areas may require 25–30 mm.

How do I maintain inorganic terrazzo?

Regular cleaning with water or neutral pH cleaners is sufficient. Inorganic terrazzo is resistant to efflorescence, cracking, and delamination, minimizing long-term maintenance costs.

Is inorganic terrazzo safe for hospitals and sensitive environments?

Yes. It contains no resin or VOCs, complies with strict hygiene standards, and is easy to disinfect, making it suitable for hospitals, clinics, and laboratories.

Can colors and patterns be customized?

Absolutely. Inorganic terrazzo allows customization of aggregate types, colors, ratios, and textures, enabling designers to create unique, branded, or architectural aesthetics.

How durable is inorganic terrazzo compared to traditional terrazzo?

Thanks to high Mohs hardness (up to Grade 5), high density, and fire resistance, inorganic terrazzo is more resistant to scratching, rolling loads, UV exposure, and moisture, making it more suitable for demanding commercial and public projects.

Where can I source high-quality inorganic terrazzo?

Reliable suppliers like Wayon provide China terrazzo slabs, tiles, and full project support with detailed test reports, consistent supply, and guidance for installation and maintenance.

Ready to elevate your commercial project with long-lasting, design-forward inorganic terrazzo? Claim your free samples, explore free custom style development, and choose from over 100 vibrant terrazzo design options—perfect for designers seeking bold, expressive material solutions.