Silica-Free Quartz Solutions: Compliance, Safety, and Engineering Excellence

With Australia officially implementing a ban on silica-containing engineered stone on July 1, 2024, designers, contractors, and developers are increasingly seeking materials that meet stringent regulatory standards without compromising durability or aesthetics.

In the evolving landscape of construction and engineering materials, zero silica quartz is emerging as a leading choice for projects that prioritize safety, compliance, and long-term performance. Wayon’s silica-free quartz has positioned itself as a reliable building material solution for these needs, offering unmatched safety and engineering performance.

What is Zero Silica Quartz?

Zero silica quartz, also referred to as silica-free quartz, is engineered stone designed to eliminate crystalline silica entirely from its composition. Traditional quartz surfaces, while popular for countertops, flooring, and wall cladding, often contain high levels of crystalline silica, a material that poses significant health risks when inhaled as dust. Silica-free quartz provides the same structural and visual qualities as conventional quartz but removes this health hazard at the source.

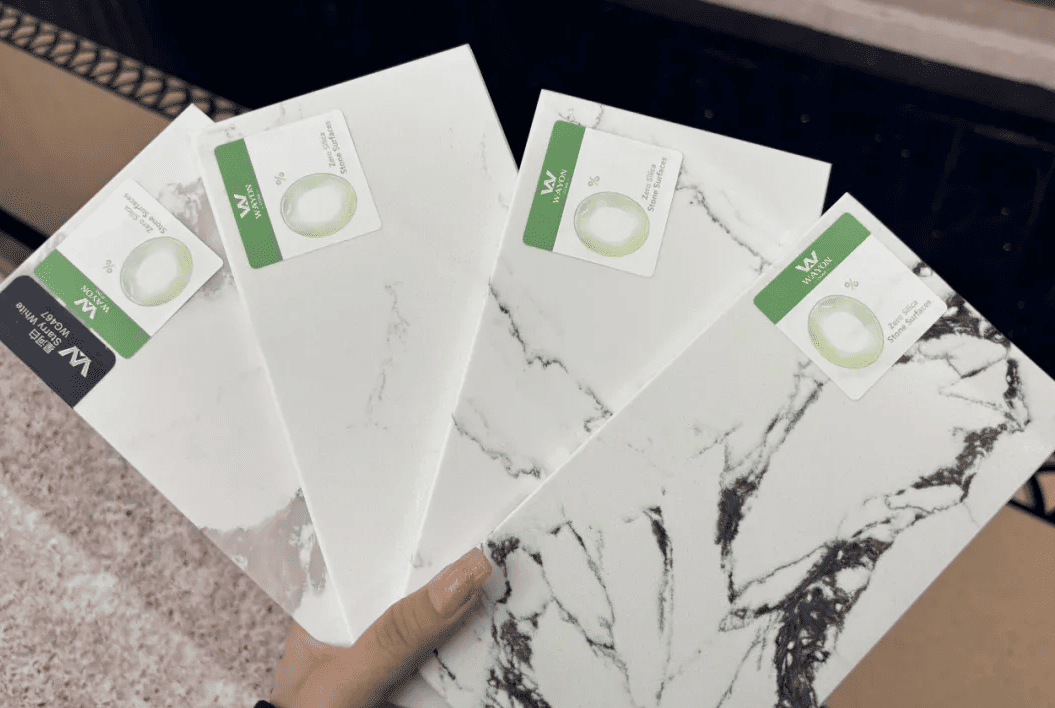

Wayon silica-free quartz takes this a step further by offering materials that are verified as “true zero silica” through multiple international and local laboratory certifications. This positions it as a preferred choice for projects with strict safety requirements, including hospitals, commercial centers, and high-traffic public spaces.

China Zero Silica Quartz Factory

Wayon’s Zero-Silica Quartz: Setting a New Standard

1. Health & Safety Advantages: Tested, Certified, Trusted

The most significant advantage of zero silica quartz lies in its critical contribution to occupational and public health. During the processing of traditional engineered quartz, crystalline silica dust with particle sizes as small as 1–5 micrometers is generated. These ultra-fine particles can penetrate deep into the lungs, bypass natural respiratory defenses, and lead to severe and irreversible conditions such as silicosis, lung cancer, and other chronic respiratory diseases.

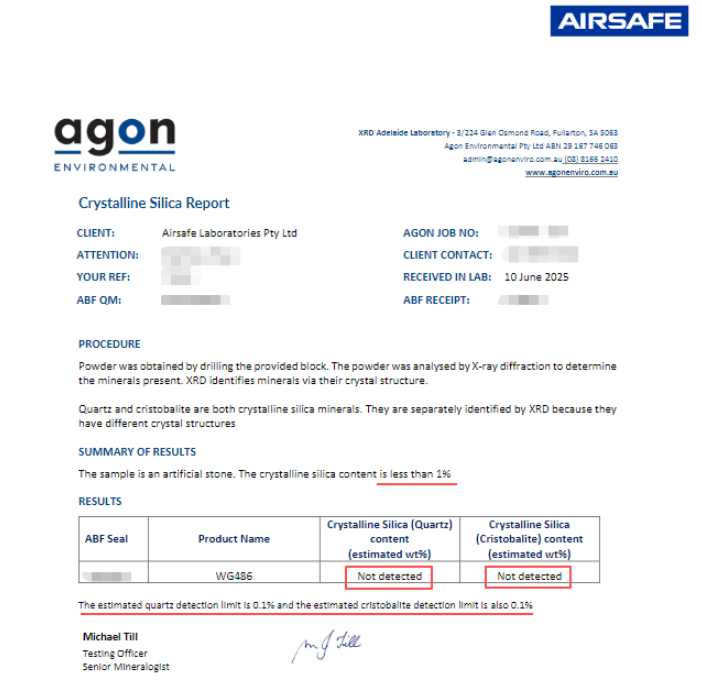

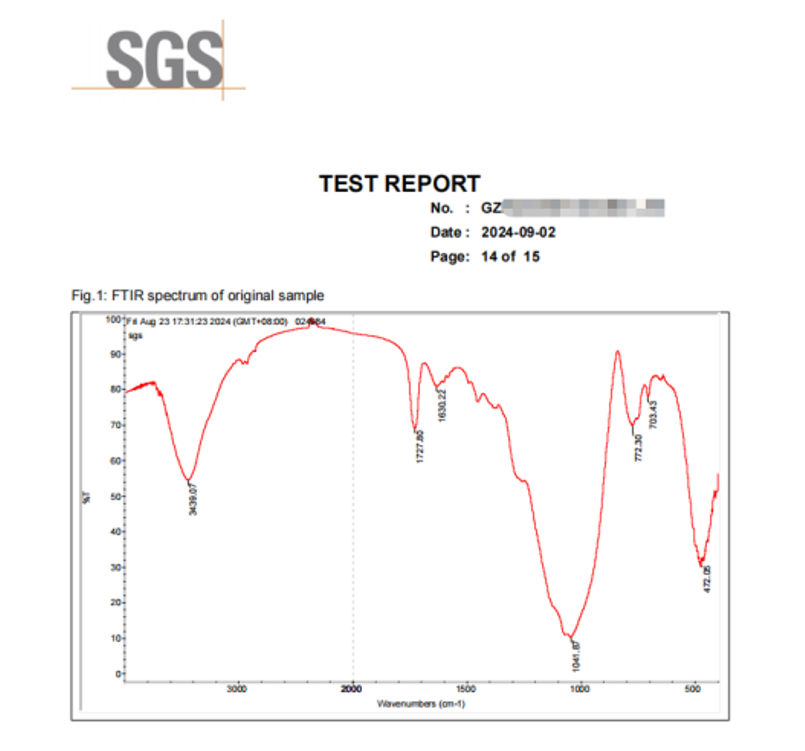

Being a leading silica-free quartz supplier in China, Wayon eliminates this risk at the source by completely removing crystalline silica from its composition. Independent testing conducted by Airsafe Laboratories (Australia) and Agon Environmental confirmed that no quartz or cristobalite was detected in the material. These results significantly exceed the industry’s standard threshold of ≤1%, and even surpass Wayon’s own internal control benchmark of ≤0.5%, demonstrating exceptional material purity and precision.

Dual Laboratory Certification: Airsafe Laboratories & Agon Environmental

Furthermore, verification by SGS, a globally recognized testing authority, confirmed that Wayon’s silica-free quartz is composed of 89% glass and 11% unsaturated polyester resin, ensuring there is no potential for silica dust exposure throughout fabrication, installation, or use.

As a result, Wayon’s zero silica quartz is particularly well suited for environments where health and safety are paramount, including:

- Hospitals and clinics

- Laboratories and medical facilities

- Schools and daycare centers

- High-traffic commercial spaces such as airports, shopping malls, and hotels

By eliminating the health hazards associated with traditional engineered quartz, Wayon’s zero silica quartz delivers a safer working environment for professionals and a healthier living space for the public, setting a new benchmark for responsible and future-ready building materials.

2. Engineering-Grade Performance: Stability for Extreme Conditions

Zero silica quartz is not only safer but also engineered to meet demanding structural and aesthetic requirements. Wayon’s products have undergone rigorous testing to verify mechanical performance under extreme conditions, ensuring reliability for large-scale engineering projects.

Key performance of Wayon silica-free quartz:

|

Metric |

Value / Description |

Test Standard / Notes |

|

Mohs Hardness |

6–7 |

Suitable for high-use and high-abrasion surfaces |

|

Compressive Strength (Dry) |

175 MPa |

ASTM C170 |

|

Compressive Strength (Wet) |

163 MPa |

ASTM C170 |

|

Flexural Strength (Dry) |

58.6 MPa |

ASTM C880 |

|

Flexural Strength (Wet) |

53 MPa |

ASTM C880 |

|

Uniform Load Capacity |

≥300 kg/m² |

Suitable for airports, shopping malls, and other high-traffic public spaces |

|

Impact Resistance |

9.05 J |

High resistance to accidental impact |

|

Water Absorption |

≤0.01% |

Excellent stain resistance and low chemical susceptibility |

Wayon’s zero silica quartz withstands high loads and heavy foot traffic, meeting the demands of airports, malls, and other high-traffic spaces. Its low porosity and chemical resistance allow long-term exposure to disinfectants and cleaning agents without damage, making it ideal for medical, laboratory, and commercial environments.

Also, silica-free quartz from Wayon offers excellent wear and heat resistance, enduring thousands of abrasion cycles and direct contact with high-temperature surfaces without scratching, discoloration, or harmful effects.

With durability, safety, and low maintenance, Wayon’s zero silica quartz delivers reliable performance in any high-use setting.

Zero Silica Stone Manufacturer in China

3. Global Compliance: Ready for International Markets

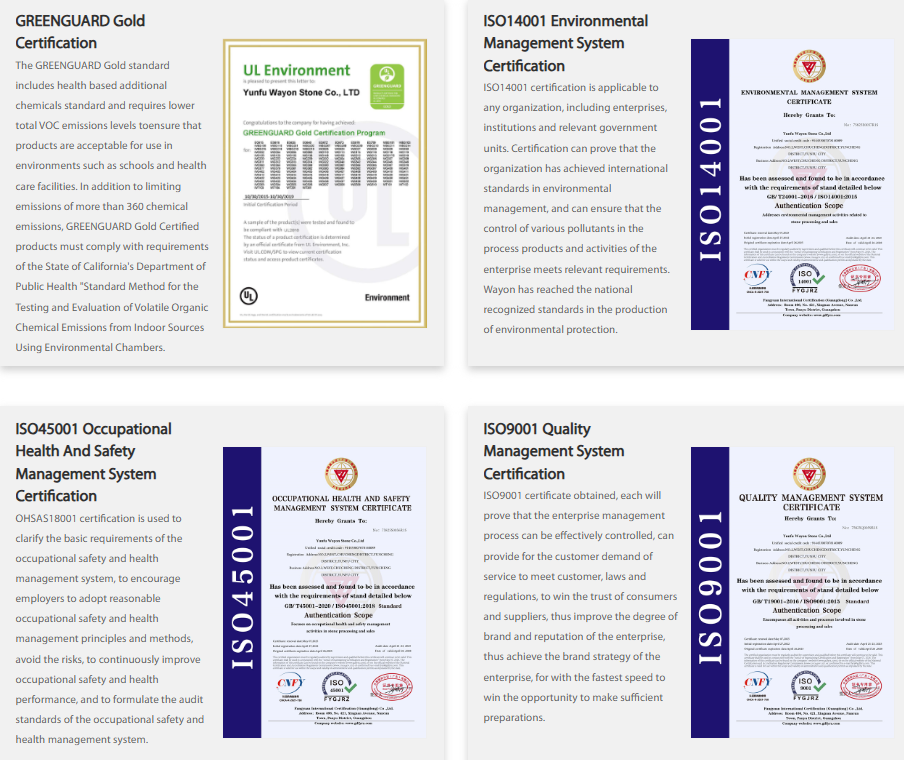

For projects targeting international markets, regulatory compliance is a critical consideration. Wayon zero silica quartz holds certifications from multiple globally recognized standards, ensuring seamless integration into various regulatory frameworks:

- ISO 9001: Quality management system

- ISO 45001: Occupational health and safety management

- ISO 14001: Environmental management

- CE Certification: Compliance with EU safety standards

- Greenguard Gold: Indoor air quality certification for schools and hospitals

- NSF Certification: Safe for food contact applications

These certifications confirm that Wayon’s silica-free quartz meets the highest international standards for safety, quality, and environmental responsibility. Today, the material is successfully used in over 50 countries and regions worldwide, from high-end hotels in Asia to commercial complexes in Europe, food processing facilities in North America, and public buildings in Australia, providing a proven solution that meets diverse regulatory requirements across the globe.

4. Engineering Efficiency: Optimized Production-to-Installation

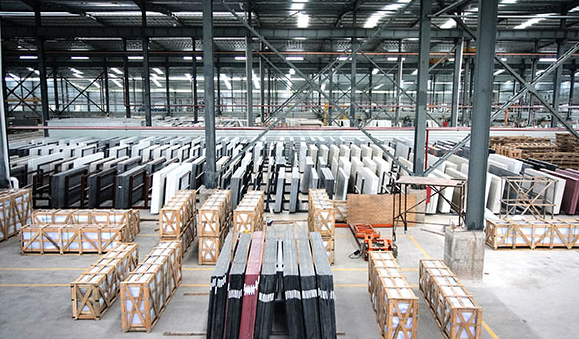

Wayon’s zero silica quartz is engineered to meet the demands of large-scale construction and commercial projects. With four major production and processing facilities delivering over 3 million square meters annually, Wayon provides a reliable, large-scale supply to support global projects.

Additionally, Wayon offers project-specific customization, including:

- Pre-fabricated slabs to reduce on-site cutting and material waste

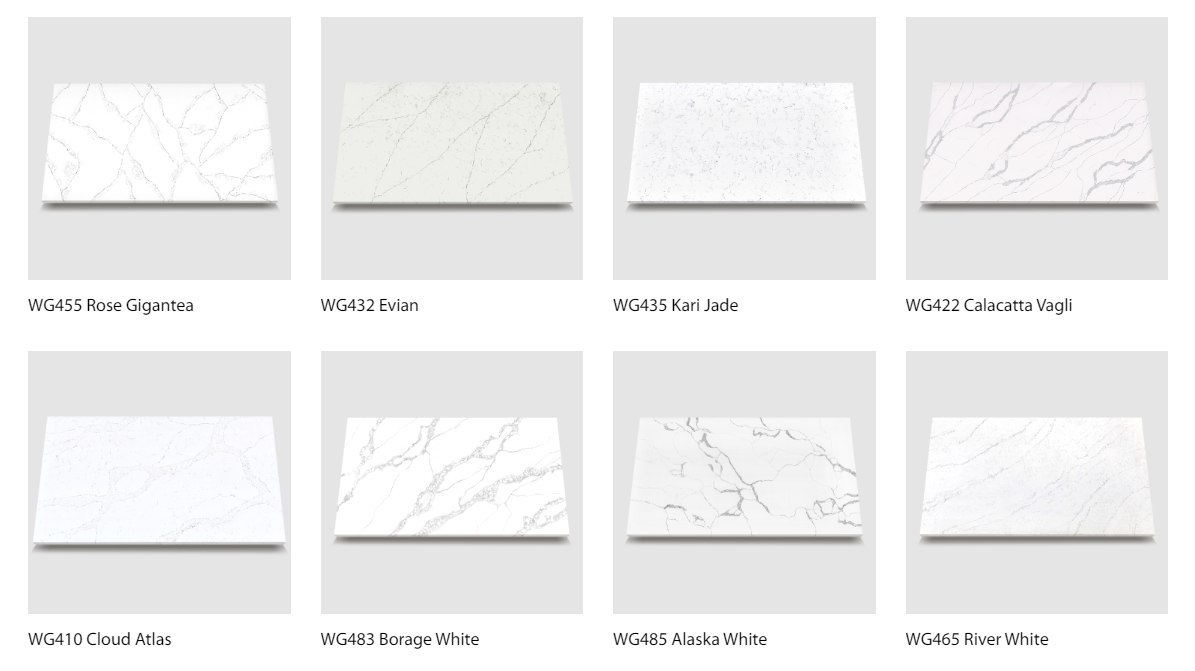

- Tailored surface textures, colors, and patterns for aesthetic flexibility

- BIM integration support for precise installation planning

- Technical guidance for unique fabrication challenges and installation

- Maintenance support for repairs, refinishing, and extended durability

An experienced engineering support team from Wayon assists clients throughout the project lifecycle, from initial material selection to installation and post-installation maintenance. This comprehensive service ensures that projects can be completed efficiently without compromising safety, quality, or timelines.

Zero Silica Quartz Factory In China

Silica-Free Quartz Case Studies: Proven Results

Wayon zero silica quartz has been successfully applied in various high-profile projects worldwide, including:

- Australian public buildings and commercial centers adhering to the new CSS ban regulations

- High-end hotels and luxury residential projects in Europe

- North American food processing facilities requiring NSF-certified materials

- Asian healthcare and laboratory environments

These cases demonstrate not only compliance with local and international regulations but also the durability, aesthetics, and safety of Wayon’s silica-free quartz in real-world applications.

Wayon Silica-Free Quartz For Commercial Projects

Why Choose Wayon Silica-Free Quartz?

Wayon has over 43 years of experience in the engineered stone industry, offering a proven track record in material innovation and project support. As a leading silica-free quartz manufacturer in China, Wayon's zero silica quartz stands out for:

- Health and Safety: Complete elimination of crystalline silica risk

- Engineering Excellence: Verified mechanical and chemical performance for demanding applications

- Global Compliance: Certifications across multiple international and regional standards

- Comprehensive Project Support: From customization to technical guidance and aftercare

For construction professionals, designers, and project managers, Wayon provides a complete zero silica quartz solution that combines safety, performance, and aesthetic flexibility.

Conclusion

As regulatory environments tighten and the health risks of crystalline silica become more widely recognized, zero silica quartz has become an essential material for modern construction and engineering projects. Wayon’s silica-free quartz not only meets these standards but exceeds them, providing verified safety, engineering reliability, and global compliance.

For developers, architects, and commercial project teams seeking a trusted, high-performance material, Wayon silica-free quartz offers a complete, end-to-end solution from product development to installation.

Contact Wayon today to request samples and technical documentation, and ensure your next project leverages the benefits of zero silica quartz for safety, compliance, and long-term value!