Solve Stone Engineering Problems - WAYON STONE One-Stop Stone Engineering Solutions

WAYON STONE

ONE-STOP SUPPORTING SERVICE SOLUTIONS

Question time!

Are you always struck by these thunders when you are engaged in stone engineering?

●If the quality of the material is not good, the material manufacturer and the processing factory will blame each other!

●The processing is so rough that it cries: the cabinet seams are large, the bathroom basins are cut off, the furniture is ugly, and the wall and floor patchwork is messy!

●Transportation will crack as soon as you touch it, and domestic cross-provincial and overseas cross-border countries are very careful!

●After-sales missing, no one will find out if there is a problem!

●I want to undertake large-scale engineering projects, but I don't have enough qualifications!

Don't panic!

Wayon plays evil repair services in the field of stone engineering - providing "one-stop engineering supporting services", steadily carrying the whole chain of "materials → processing → packaging → after-sales", and turning the "complex questions" of stone engineering into "choice questions" to solve complex problems for global engineering.

Ⅰ. Raw materials have confidence!

If you don't want stone engineering to go wrong, materials are the first hurdle. Many projects have problems because the source of materials is chaotic and the quality is not guaranteed. Wayon started from the source to make the material steady.

Wayon stone production base: factory size 60,000+㎡ → monthly output 100000+㎡ → standing inventory 30000+㎡

The confidence of Wayon Stone is hidden in the stable control of raw materials - it not only has a solid raw material reserve, but also has in-depth cooperation with high-quality raw material suppliers in many places to directly connect with the first-hand resources of the source.

Full-category stone matrix, covering multiple scenes

Relying on high-quality stone mineral resources, Wayon has developed a rich stone product line. The stone category covers a full range, including natural stone, artificial stone, new environmental protection materials, etc., which can meet various engineering needs.

●Artificial quartz: It is made of more than 90% of its own quartz sand, which has both hardness and stain resistance. It is suitable for kitchen countertops, hospital walls and other scenes. It has been internationally certified by the direct contact level of NSF food in the United States, EU CE and so on.

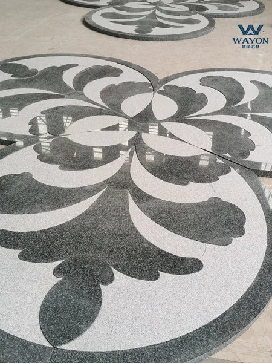

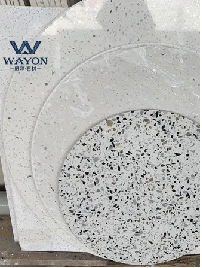

●Inorganic terrazzo: high-performance inorganic terrazzo, using inorganic adhesive, wear resistance and fireproof, low water absorption, not easy to deform and other advantages are suitable for shopping mall floors and hotel lobbyes;

●Natural stone: covering marble, granite, etc., such as Versace black, Yashibai, Prada gray, Portuguese beige, etc., with unique texture adapting to high-end decoration;

●Gemstones: Selected natural raw material slices, which are manually stitched, filled, and polished to make the surface smooth and delicate. It can be designed and stitched on demand to meet the creativity of personalized space. ;

●New environmental protection materials: rock slab (high temperature and high pressure molding, high humidity resistance), cement stone (inorganic environmental protection, suitable for internal and external walls), soft stone (flexible materials, suitable for curved surface decoration), etc., covering the needs of architectural decoration in an all-round way.

From material screening to finished product delivery, Wayon stone integrates into a variety of inspections and tests, and is regularly sent to third-party national stone testing centers and international authoritative testing institutions such as SGS.

The company's products have also been certified by Greenguard Gold in the United States for low VOC emissions, which are suitable for hospitals, schools and other places with high environmental requirements.

Ⅱ.Stable machining accuracy!

Wayon Machining Center has a 6,500m2 factory building, equipped with a series of advanced equipment, and has passed the ISO9001 quality management system certification. The processing system strictly conforms to national standards. We also independently develop Quartz Qecoration Design Software (registered by the national copyright), from design simulation to typesetting optimization, and digitally empower the processing accuracy. For the four scenes of walls and floors, cabinet countertops, bathroom space and furniture countertops, the exclusive processing process is customized to accurately "sold" stone into engineering-appropriate finished products.

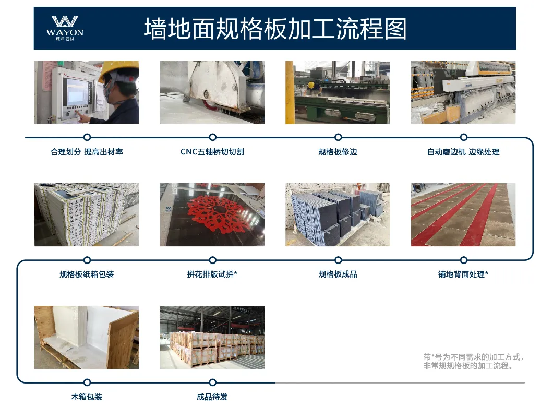

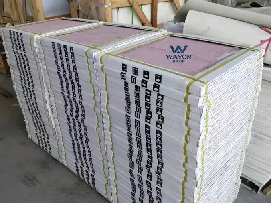

Wall and floor specification board

Wayon standardized wall floor specification processing process:: reasonable division to improve the shipping rate → CNC five-axis bridge cutting → specification board trimming → automatic edge grinding machine edge processing → back paving → specification board finished product → mosaic type matching → specification board carton package → wooden box package → finished product ready to be shipped.

Both efficient utilization and stability

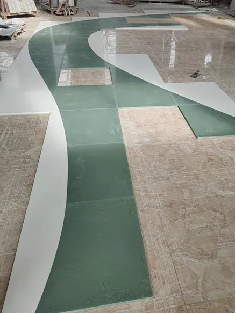

Reasonably divide the plate to improve the yield, and the parquet design can be tried in advance to ensure pattern alignment;

Automatic edge grinder handles edges, special treatment on the back of the pavement enhances adhesion, and is suitable for large space paving such as shopping malls and subways.

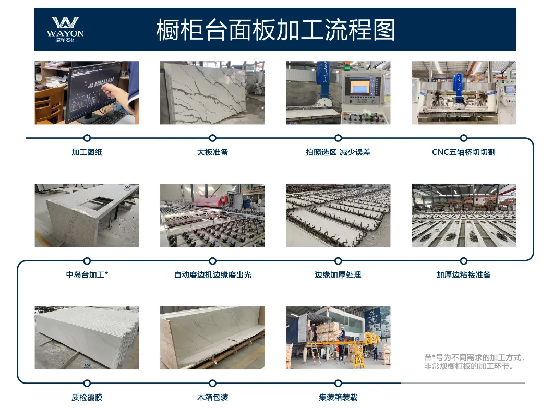

Cabinet countertop

Wayon standardized cabinet table panel processing: processing drawings → large board preparation → photo selection reduce errors → CNC five-axis bridge cutting → thickened edge adhesive preparation → thickened edge treatment → automatic edge grinder edge polishing → Zhongdao table processing → quality inspection coating → wooden box packaging → container loading.

"Zero error tolerance" from large boards to finished products

The Italian five-axis bridge cutting machine accurately cuts, with a hole position and cutting angle error of ≤0.5mm, and the middle island platform and shaped countertop can be customized;

The automatic edge grinding machine processes the edges, from light output to thickening seamless connection, and finally through quality inspection, film coating and wooden box packaging to ensure transportation safety.

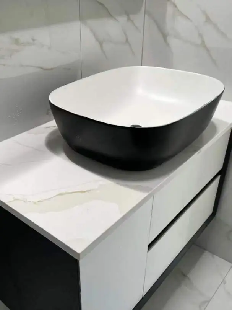

Sanitary space

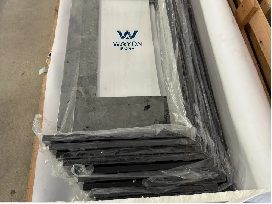

Wayon standardized finished bathroom processing: design and processing drawings → precision processing → Italian CNC five-axis bridge cutting machine 45%-degree cutting → CNC CNC opening → semi-finished product preparation → thickened edge bonding preparation → bathroom all-in-one basin sticking firmness → quality inspection finished product splicing details → packaging sealing film → box packaging by floor label → loading and delivery.

Seamless stitching and detail polishing

Italian CNC equipment for 45° cutting edge, one-piece basin splicing gap ≤0.3mm, with fine polishing of the inner edge of the sink, taking into account beauty and practicality;

Box packaging by floor, convenient domestic transportation, clear overseas customs clearance labels, adapting to the needs of global projects.

Sanitary space

Wayon standardized furniture countertop processing: processing drawings → furniture table panel selection cutting → CNC five-axis bridge cutting machine multi-angle cutting → check the drawings item-by-item inspection → grinding chamfering → edge processing → high accuracy semi-embedded corners → accessories trial installation → finished packaging sealing film → wooden box packaging careful inventory → loading and departure.

Multi-angle processing realizes "design freedom"

CNC five-axis bridge cutting machine supports personalized cutting such as curved and semi-embedded edges to meet the designer's creativity;

The fittings are tested before leaving the factory to ensure a perfect adaptation to the metal bracket, etc., with a detailed installation guide, which is worry-free for domestic and overseas construction.

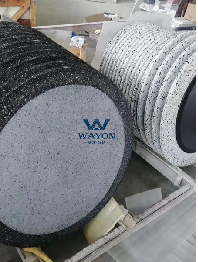

Ⅲ.Transportation does not overturn!

If the stone is processed more precisely, there will be a slight bump, moisture, and displacement in transportation, and the early process advantages may be in vain. Wayon builds a full-process scheme around "zero damage delivery", from veneer protection to the whole cabinet sealing, and controls every link with data-based rules, so that the stone can safely reach the project site.

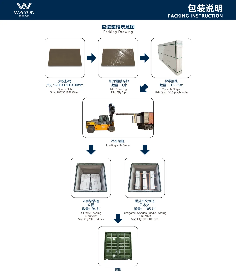

Wayon standardized transportation packaging: large plate → plate coating protection → strap binding → crane cabinet → A-shaped rack cabinet (6 bundles) / fumigated wooden frame cabinet (7 bundles) → sealed cabinet

Full-scene protection system

Basic protection: from single pieces to bundles, build the first line of defense

Single board coating: Each piece of stone is fully wrapped in film, which is isolated from water vapor and dust. Whether it is the southern rainy season or in dry areas, the stone surface can be kept clean;

Whole bundle reinforcement: 15-16 pieces are a bundle, and the high-strength straps are cross-fixed. The impact resistance test shows that the load of a single bundle can reach 2.4 tons, and it is not easy to fall apart to cope with frequent loading and unloading.

Scenario adaptation: flexible packaging scheme to adapt to all kinds of transportation needs

Wooden rack / wooden clamp combination: removable wooden racks are customized according to stone specifications. Large-size plates are matched with A-shaped shelves to disperse pressure, and small and medium-sized specifications are reinforced with fumigated wooden clips, which not only meet transportation specifications, but also save space;

Detail protection: Hard plastic corners are equipped with corners, gaps are filled with buffer pads, and moisture-proof layers or crack-proof pads are added for different climate areas to ensure the stable performance of stone in various environments.

Ⅳ.After-sales service is guaranteed!

The stone engineering cycle is long and there are many links, and any omissions may slow down the progress. Wayon not only establishes a full-cycle response mechanism, but also visits the construction site regularly to investigate the hidden dangers of stone installation and use in advance. From leaving the factory to delivery for use, it can respond quickly whether it encounters quality, transportation or maintenance problems.

Quality issues

Source control, if there is a problem, solve it

If there are factory quality problems in the stone (such as structural cracks of natural stone, large-area defects in artificial stone, specifications/thickness inconsistent with the order, color difference exceeding the agreed range, etc.), Wayon will provide return and exchange services, or negotiate discount according to the actual situation, and never let unqualified products affect the progress of the project.

Transportation and delivery issues

Responsible for the whole process, leakage package repair

Damaged in transportation: Stone is a fragile product. If it is damaged due to improper packaging, Wayon will reissue the damaged part. Small gaps can also provide maintenance cost support, so as not to let customers pay for transportation risks;

Delivery error: If there is a missing hair, wrong hair number or quantity, etc., we will respond within 24 hours, and give priority to reissue or replacement to ensure that the engineering materials are in place in time.

Use and maintenance

After-sales service, let the stone "long-term protection as new"

If there are problems such as non-human cracking, empty drum, surface wear, etc. during the use of stone, Wayon can provide professional maintenance services, including filling cracks, partial renovation, etc., to extend the service life of the stone and make the engineering effect last long.