Top Stone Manufacturer in China: Wayon One-Stop Stone Engineering Solutions

In stone engineering projects, problems rarely come from design ideas. Most headaches start later, when drawings meet reality. Materials arrive late, colors do not match samples, installation standards vary from team to team, and small mistakes turn into expensive rework. For many contractors and developers, stone work becomes the most unpredictable part of the whole project.

This is exactly the pain point Wayon Stone has been focusing on since its early days.

Founded in China in 1982, Wayon Stone is now recognized as a leading stone manufacturer and engineering solution provider, offering not only materials, but a complete one-stop stone solution covering design support, material supply, processing, packaging, delivery, installation coordination, and after-sales service.

Top Stone Manufacturer in China

A Stone Manufacturer Built on Stable Foundations

Quality stone always starts from the source. Wayon maintains long-term control over raw materials through stable reserves and deep cooperation with premium suppliers. This direct access to first-hand resources helps avoid quality fluctuation, color inconsistency, and supply interruption, especially in large-scale engineering projects.

By controlling materials from the beginning, Wayon ensures every batch meets the same performance and appearance standards, even across long project cycles.

Full-Category Stone Solutions for Real Projects

Wayon offers a complete range of natural, engineered, and environmental-friendly stone materials, allowing designers and contractors to work with one reliable supplier across different spaces. Main product categories include:

- Quartz stone, widely used for kitchen countertops, hospital walls, and laboratory surfaces due to high hardness and stain resistance

- Inorganic terrazzo, suitable for shopping malls, hotel lobbies, and public floors with high traffic and fire-resistance requirements

- Natural stone, including marble and granite varieties such as Prada gray, Portuguese beige, and other premium selections

- Gemstone stone, manually stitched and polished for feature walls, furniture tops, and artistic interiors

- New environmental materials, such as porcelain slabs, cement stone, and flexible stone for curved surfaces and complex structures

All products are tested regularly and meet international standards including NSF food contact, EU CE, and Greenguard Gold certification.

Advanced Processing That Improves Construction Accuracy

Good materials still need precise processing. Wayon’s Stone Processing Center covers more than 6,500 square meters and is equipped with advanced machinery from Italy and Taiwan. It includes five-axis bridge cutting machines, automatic edge grinding systems, CNC drilling machines, and dedicated countertop assembly lines. This strong processing capacity allows Wayon to deliver:

- Customized kitchen countertops and bathroom vanity tops

- Furniture table tops and special-shaped stone products

- Wall panels and floor tiles with consistent sizing and finish

Standardized fabrication helps reduce on-site cutting, speeds up installation, and improves overall construction efficiency.

Why are One-Stop Stone Solutions Important?

The biggest challenge in stone engineering is coordination. Wayon’s one-stop engineering supporting service connects every step, from early design to final delivery. Instead of managing multiple suppliers, clients work with one experienced partner. We offer:

- Synchronized design and material selection, ensuring that stone types, colors, and processing details are practical and buildable

- Integrated supply and construction support, backed by Wayon’s own production bases and standardized processing

- After-sales service and maintenance guidance, helping prevent cracking, staining, and premature wear

By managing the full chain, Wayon helps improve schedule accuracy by around 40% and extends the service life of stone applications.

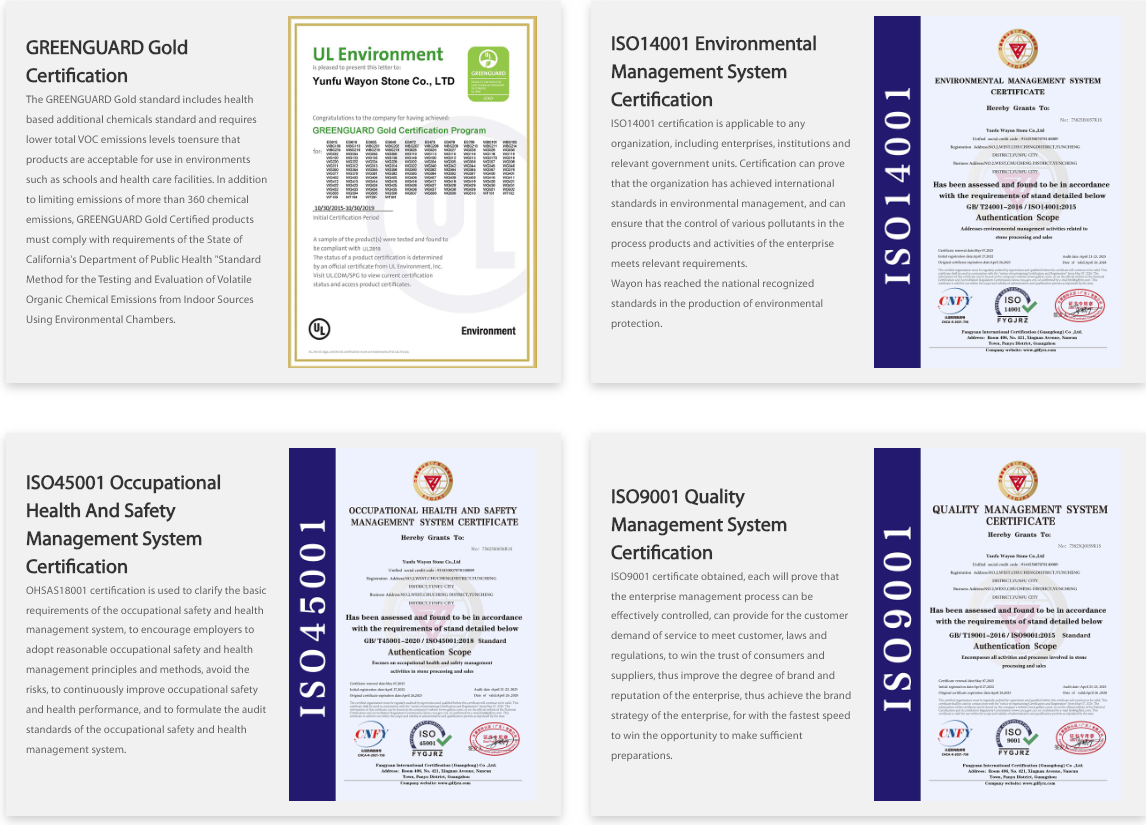

Certifications That Reflect Real Capability

Wayon’s quality system is supported by a complete set of international certifications. We hold Greenguard Gold and Greenguard Indoor Air Quality certification, making its products suitable for hospitals, schools, and other sensitive environments. Wayon also meets NSF food safety standards, EU CE requirements, and operates under ISO 9001, ISO 14001, and ISO 45001 systems.

Wayon has passed SGS and BV global factory audits and participated in drafting China’s Artificial Stone Technical Specifications, demonstrating our technical leadership in the stone industry.

Safe Transportation and Zero-Damage Delivery

Transportation is often overlooked but critical. We use customized wooden racks, A-frame supports, and reinforced packaging solutions based on stone size and destination climate. Hard plastic corner protection, buffer pads, and moisture-proof layers help ensure materials arrive safely and ready for installation. The zero-damage delivery system significantly reduces on-site losses and project delays.

Reliable After-Sales Support Throughout the Project Lifecycle

Stone engineering does not end at installation. Wayon maintains a full-cycle response mechanism, with regular site visits and proactive risk checks during use. Whether issues involve surface staining, cracking, transportation damage, or maintenance questions, Wayon provides timely technical support to keep projects running smoothly.

Conclusion: Build Smarter Stone Projects with Wayon

Wayon Stone is not just a stone manufacturer in China. It is a long-term engineering partner for projects that demand quality, efficiency, and accountability.

From raw material control to advanced processing, from one-stop stone solutions to reliable after-sales service, Wayon helps developers, designers, and contractors reduce risk and improve project outcomes.

If you are planning a stone project and want fewer detours, clearer decisions, and stronger results, Wayon is ready to support you.

Browse our wide range of stone collections or finished products for more detailed information.

FAQs: Common Questions from Engineering Contractors

Q: What stone products are available for projects?

A: A full range of natural and engineered stone materials is offered to meet various project needs. This includes quartz stone, inorganic terrazzo, marble, granite, gemstone stone, porcelain slabs, cement stone, and flexible stone. These can be used for kitchen countertops, bathroom vanity tops, furniture surfaces, wall and floor tiles, and custom-shaped architectural features.

Q: Can large-scale projects get a stable and continuous stone supply?

A: Yes. With multiple production and processing bases and an annual output exceeding 3 million square meters, we can ensure consistent material supply across long project cycles, minimizing batch differences and delivery delays.

Q: How can design, material selection, and construction be better coordinated?

A: One-stop engineering support integrates design, material choice, processing, packaging, and delivery. Early alignment of stone types, colors, and processing details reduces risks of design not matching practical execution.

Q: Are customized stone products feasible for complex requirements?

A: Advanced processing centers with CNC drilling, five-axis cutting, and dedicated assembly lines allow fabrication of countertops, wall panels, floor tiles, and irregular shapes for commercial, hospitality, or residential projects.

Q: How is quality consistency ensured across different project areas?

A: From raw material selection to final inspection, every batch undergoes multiple quality checks. Products are also regularly tested by third-party labs and national stone testing centers.

Q: Are these stone materials suitable for environments with strict safety or environmental standards?

A: Yes. Materials meet Greenguard Gold, NSF food contact, EU CE, and other certifications, making them appropriate for hospitals, schools, hotels, and high-standard public spaces.

Q: How is damage prevented during transportation?

A: Stones are packaged with customized wooden racks, A-frame supports, corner protection, and moisture-proof layers, adapting to different slab sizes and climates for zero-damage delivery.

Q: What after-sales support is available during the project lifecycle?

A: Full-cycle support includes regular site visits, installation guidance, and quick response to quality or maintenance issues, helping contractors prevent delays and ensure smooth progress.