Wayon High-Performance Inorganic Terrazzo: Empowering New Value in Architectural Decoration with Pure Inorganic Genes

In architectural decoration material selection, durability, environmental friendliness, and scene adaptability are the core dimensions that determine a material’s value. Wayon High-Performance Inorganic Terrazzo, leveraging its “pure inorganic” material base and technological innovation, breaks through the limitations of traditional terrazzo and becomes a preferred decorative material for commercial spaces and public buildings. Its quality can also be intuitively verified through simple tests.

Ⅰ. Pure Inorganic Composition: Laying a Solid Foundation for Eco-friendliness and Safety

The core advantage of Wayon Inorganic Terrazzo stems from its “no organic additives” material gene:

It uses natural quartz-based raw materials (accounting for over 60%) as the core aggregate, paired with eco-friendly inorganic binders and inorganic pigments. By completely eliminating organic components (such as resin and glue), it prevents the release of harmful substances like formaldehyde and VOC from the source.

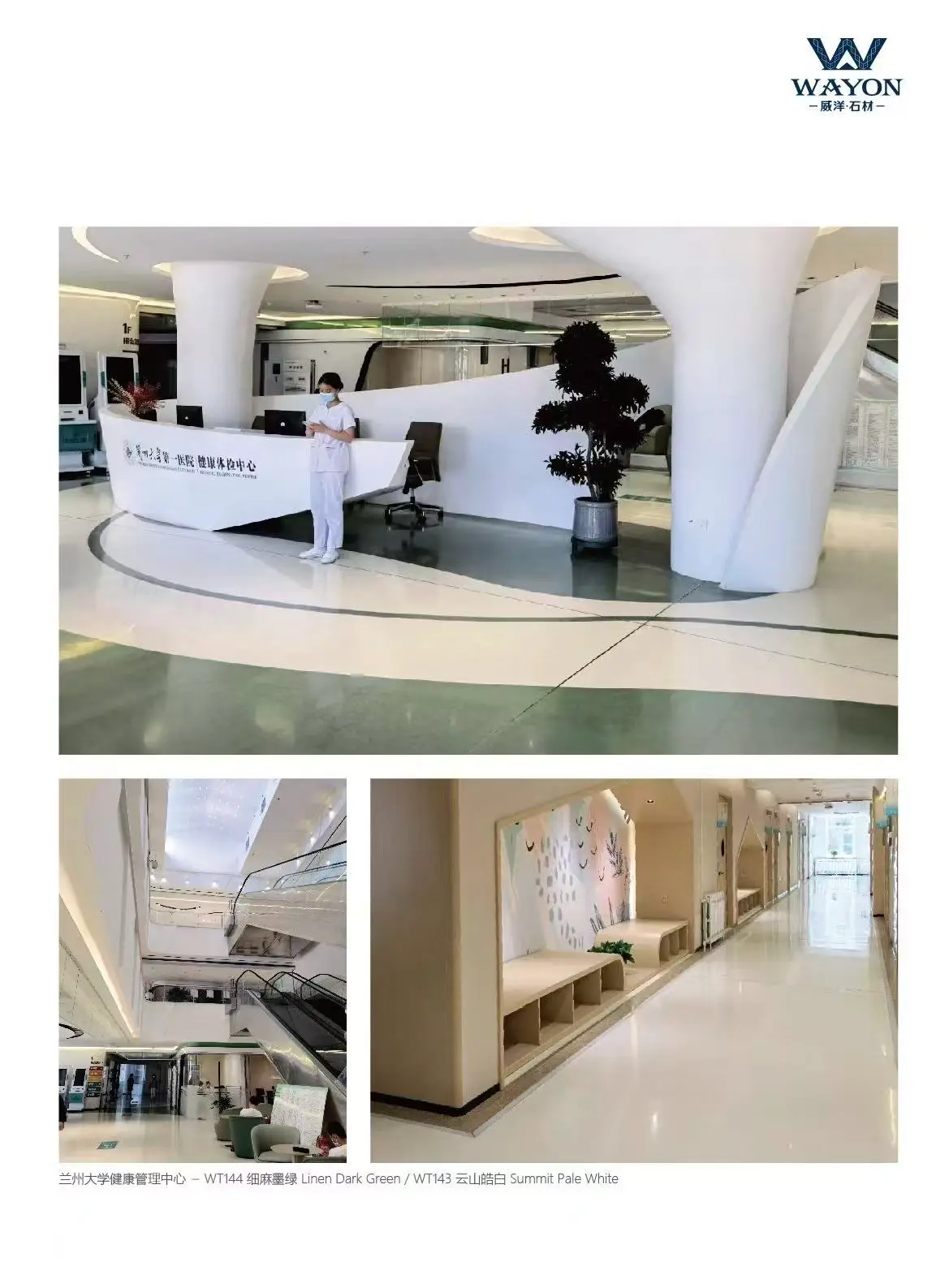

Tested to meet national green building material standards, it is especially suitable for scenarios with strict environmental requirements (e.g., hospitals, schools, and maternal-infant spaces) and aligns with modern “green building” design concepts.

(Note: Traditional organic terrazzo relies on resin bonding, which easily causes slow release of harmful substances—making it difficult to meet the needs of high-eco-standard scenarios.)

Ⅱ. Hardcore Physical Properties: Adapting to High-Frequency, High-Demand Scenarios

With the characteristics of inorganic materials and the “high-frequency high-pressure vibration forming” process, Wayon Inorganic Terrazzo demonstrates performance advantages far beyond ordinary terrazzo:

|

Inspection Item |

Organic Terrazzo |

Inorganic Terrazzo |

|

Mohs Hardness |

Grade 3 (easily scratched/worn) |

Grade 4–6 (wear-resistant & durable) |

|

Density |

<2.3 g/cm³ (loose structure) |

2.36–2.57 g/cm³ (dense & firm) |

|

Water Absorption |

≥3%(prone to alkali efflorescence/shelling) |

0.08–2.7% (alkali-resistant) |

|

Compressive Strength |

Low (prone to cracking during fine processing) |

High (supports bush-hammered finish, 45° splicing) |

|

Flammability |

Flammable (contains resin, easy to burn) |

Non-flammable (no resin; supports flamed finish) |

Hardness & Wear Resistance: Organic terrazzo is easily scratched by trolleys or high heels in high-traffic scenarios (e.g., malls, exhibition halls). Wayon Inorganic Terrazzo, with its high hardness, maintains a flawless surface after long-term use—reducing maintenance costs.

Alkali Resistance: Organic terrazzo’s high water absorption causes “alkali efflorescence white spots” in humid spaces (e.g., swimming pools, bathrooms). Wayon Inorganic Terrazzo’s low water absorption solves this pain point, making it suitable for all humid public scenarios.

Ⅲ. Practical Testing Method: Quickly Verify Inorganic Quality

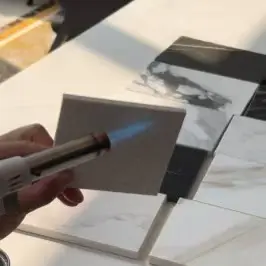

Worried about choosing “non-pure inorganic” terrazzo? The “flame test method” allows intuitive identification with simple operations and accurate results:

Choose the right tool: Avoid traditional lighters with kerosene/gasoline fuel (they produce black carbon residue that interferes with judgment). Instead, use butane-fueled tools (e.g., windproof lighters, torches)—butane burns into CO₂ and H₂O (no residue), and its flame temperature reaches 1300℃ (accurately reflecting material properties).

Observe the reaction: Heat the terrazzo surface with a butane tool for 3–5 seconds

True inorganic (Wayon product): Only slight granular cracking occurs (similar to stone “flamed finish” texture) due to the “difference in thermal expansion coefficients” of internal mineral crystals (quartz, feldspar, etc.). There is no black smoke, no pungent odor, and no melting/blackening on the surface.

Fake inorganic (contains resin): Smoke (black/white) appears within 1–2 seconds, accompanied by a plastic-burning smell. The surface melts/wrinkles locally, leaving char marks after cooling.

Ⅳ. Purchase Tips: Beware of Two Types of “Pseudo-High-Quality” Terrazzo

Some terrazzo products on the market seem “advantageous” but hide risks. When purchasing, pay close attention to:

① Terrazzo with “unrealistically short production cycles”

Cement (the core bonding component of inorganic terrazzo) requires a fixed hydration cycle (usually ≥7 days)—a process that cannot be shortened in nature. If a supplier claims “7–15 days delivery” or “fast turnaround”, they likely rushed production before cement fully reacts. This leaves hidden holes/cracks inside the slabs: while problems may not appear immediately after installation, alkali efflorescence, shelling, and surface cracking often occur after a few months—requiring costly demolition and reinstallation.

② Terrazzo with “abnormally high flexural strength”

Pure inorganic terrazzo has a reasonable flexural strength range of “≥8 MPa” (per GB/T 35164-2017). If a product claims “flexural strength >20 MPa”, it likely contains organic binders (e.g., resin, unsaturated polyester)—which boost short-term strength but cause fatal defects later:

- Poor high-temperature resistance (large-area flooring may deform, warp, or even catch fire).

- Weak UV resistance (fades/discolors after short-term outdoor use).

- Strong odor during cutting/processing.

If in doubt about “true inorganic” status, use the butane flame test: True inorganic terrazzo only cracks slightly (no combustion/smoke); terrazzo with organic components smokes and melts—making authenticity easy to distinguish.

Ⅴ. Full-Scene Durability: Withstand Extreme Extreme Environments

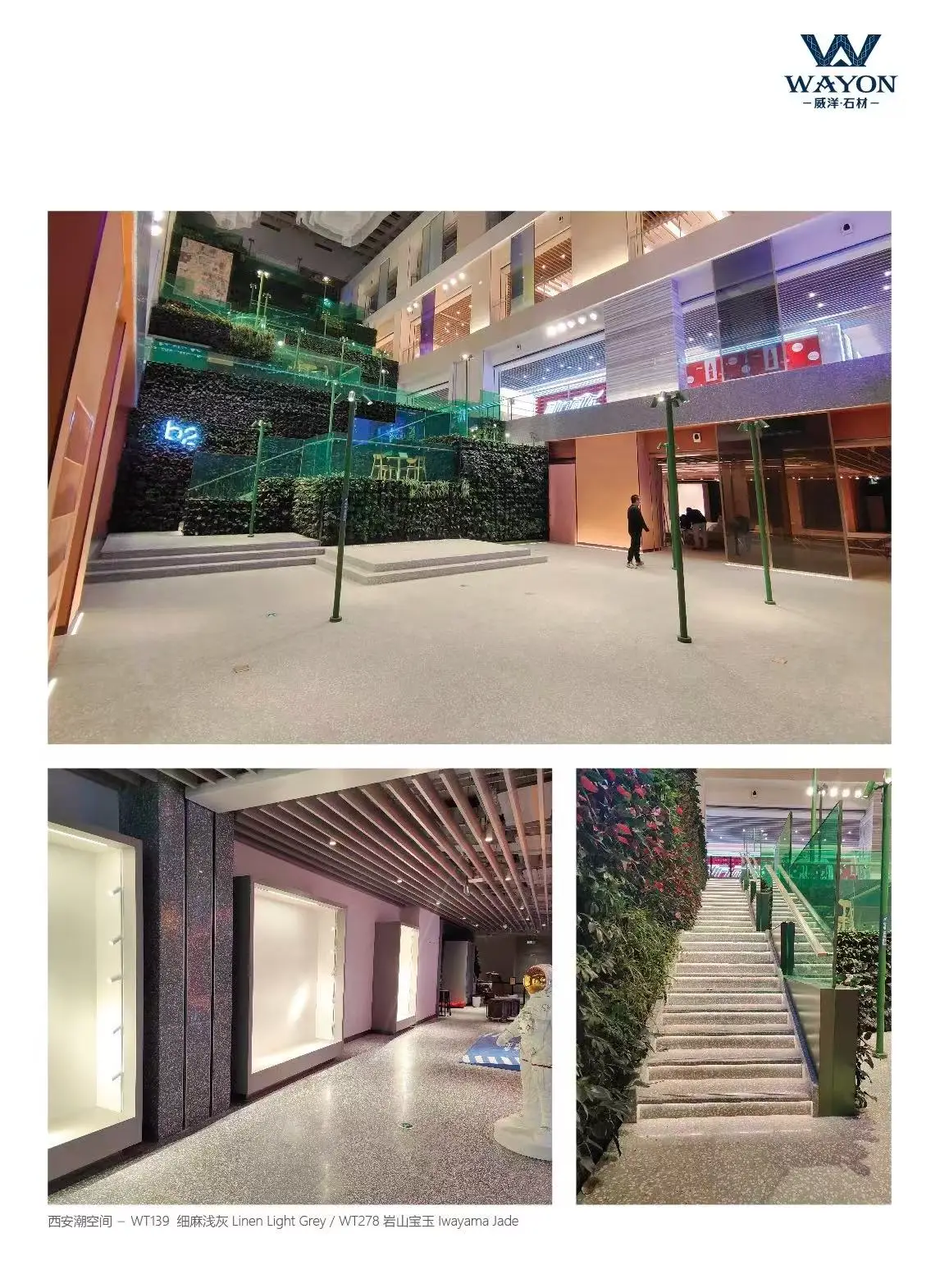

Inorganic materials give Wayon Terrazzo “full-environment adaptability”, breaking traditional materials’ scene limitations:

Fire & freeze resistance: Natural inorganic components tolerate high/low temperatures—suitable for extreme scenarios (e.g., northern outdoor squares, high-temperature kitchens).

Corrosion & UV resistance: Resists acid/alkali chemical erosion (ideal for labs, chemical plants, hospitals) and doesn’t fade/deform outdoors (perfect for commercial streets, municipal landscapes).

Long-term freshness: No yellowing or pores over time, maintaining a like-new surface—solving traditional terrazzo’s “easy aging/damage” pain points.

Ⅵ. Efficient Construction & Maintenance: Details Determine Long-Term Durability

① “Back glue treatment” is essential for large-area paving

To prevent later cracking/deformation when laying inorganic terrazzo, back glue application is key. Principle: Back glue forms a dense waterproof layer on the slab’s back, blocking moisture from walls/ground from penetrating the slab. This avoids stress between the cement base and slab (caused by humidity differences), preventing cracking and alkali efflorescence. We provide a Terrazzo Factory Installation Guide with detailed back glue construction steps, tool lists, and precautions.

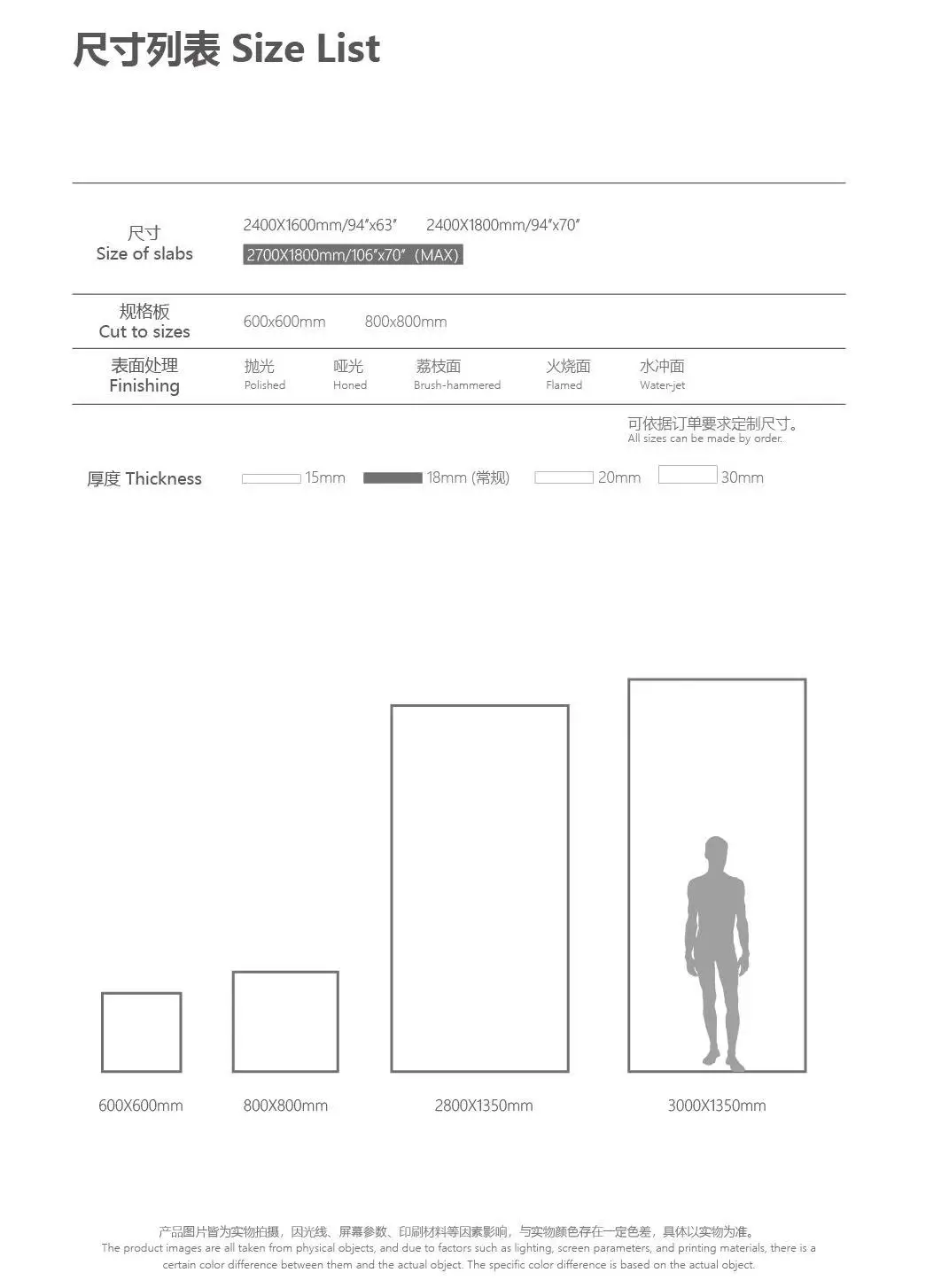

② Choose slab thickness rationally

Different scenarios require matching thicknesses to balance durability and construction convenience:

Indoor flooring: 18–20mm thickness is recommended (20mm is optimal)—meets daily wear needs without overloading floors (suitable for malls, exhibition halls, hospital corridors).

Outdoor flooring: 25mm thickness is recommended (to withstand wind/rain erosion and freeze-thaw cycles)—ideal for squares, outdoor corridors, municipal landscape grounds.

③ Low maintenance costs

Easy upkeep: Daily cleaning only requires a damp cloth (no alkali efflorescence, cracking, or shelling).

Long-term value: Saves annual labor/material costs for repeated repairs—offering higher cost-effectiveness over time.

Ⅶ. Brand Endorsement: Over 40 Years of Craftsmanship, Ensuring Inorganic Quality

Wayon Stone has focused on the stone industry for over 40 years. With its own mines, professional R&D centers, and branches in Guangdong, Yunfu, Shanghai, etc., it controls quality throughout the process (from raw material mining to finished product delivery). It has provided high-performance inorganic terrazzo solutions for projects like Xiyue Hotel, Jiangsu SOLO Swimming Club, Xiamen Zhongyu Vision Ocean Kingdom, Lijiang Yulong Snow Mountain Tourist Center, and municipal projects—backed by both reputation and strength.

Wayon High-Performance Inorganic Terrazzo, with its “pure inorganic, high durability, and full-scene adaptability” advantages, completely surpasses organic terrazzo. Its quality can be verified via simple flame tests. Whether for the long-term aesthetics of commercial spaces or the safety/eco-friendliness of public buildings, it is a preferred decorative material that balances “quality” and “efficiency”.