Wayon Zero Silica Quartz Stone: Building a Healthy Defense Line for Engineering

In the field of engineering construction and stone application, a change with compliance and safety as the core is quietly taking place. When the Australian government officially implemented the ban on artificial stone containing silica on July 1, 2024, large-scale projects, engineers and designers around the world turned their attention to the breakthrough material of "zero silica quartz stone".

Engineering-grade zero silica technology: How does Wayon stone break through the pain points of the industry?

For large-scale projects, the compliance and stability of materials are the primary consideration. Wayon stone silica quartz solves the engineering problems of traditional quartz from the roots through technological innovation:

Crystalline silica control: "true zero silica" far lower than international standards

Test Report 1: Airsafe Laboratories

![]()

The crystalline silica control of Wayon stone silica-zero quartz has reached an ultra-rigorous level - after detection by the Australian Authority (Airsafe Laboratories), the core crystalline silica minerals (quartz and quartz) in Wayon stone quartz products show "Not detected"; and the laboratory's detection limit for quartz and quartz is only 0.1%, which directly confirms that the actual content of silica dioxide of Wayon stone silica-sili quartz is much better than the enterprise internal control standard of "≤0.5%" (industry general standard is ≤1%).

Significance of market access:

This result directly proves that our products are not restricted by the Australian CSS ban and have barrier access to strictly regulated areas such as NSW, and are one of the few zero silica materials in similar products that have been verified by XRD diffraction.

Double laboratory endorse:

- Airsafe Laboratories: a well-known testing institution in Australia, with AS/NZS ISO 17025 certification;

- Agon Environmental: Professional Mineral Analysis Laboratory (ABN 29 167 746 063), using XRD crystal structure analysis;

Test Report 2: SGS

![]()

- Component analysis clearly shows that "Characteristic peak of quartz (crystalline silica) was not found"

- The main ingredients are 89% glass + 11% unsaturated polyester (UP resin)

- The data is tested by SGS authority (global certification body)

The core advantage of Wayon stone zero-silica quartz stone: comprehensive transcendence from health to performance

1. Health and safety: Build a protective wall for the whole scene

The particle size of silica dust produced during traditional quartz processing is only 1-5 microns, which can directly penetrate the lung barrier, while Wayon stone zero silica quartz eliminates this risk from the source. Whether it is engineering construction personnel, patients in hospitals and clinics, visitors to commercial spaces, passengers of airports and railway stations, and guests of hotels and apartments can be fully protected.

![]()

Detection method:

By drilling holes in the mass samples provided, the minerals in the powder are analyzed by X-ray diffraction (XRD) (XRD identifies minerals according to the structure of mineral crystals). Quartz and square quartz are crystalline silica minerals. Due to the different crystal structure of the two, they can be identified separately by XRD.

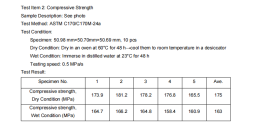

- Engineering-grade performance: adapt to the stability of extreme scenarios

For the complex environment of large-scale projects (such as high temperature, high humidity and high-frequency use), Wayon stone silica quartz has been verified by engineering-grade tests:

- Mechanical performance: Mohs hardness level 6-7, compressive strength: dry 175MPa / wet 163MPa (ASTM C170) bending strength: dry 58.6MPa / wet 53MPa (ASTM C880) can withstand a uniform load of 300kg/m2 (to meet the ground needs of high-flow places such as airports and shopping malls);

- Anti-fouling and impervious: the water absorption rate is ≤0.01%, chemical corrosion resistance (can withstand long-term immersion of disinfectant and detergent), medical, laboratory and other scenarios do not need frequent maintenance.

- Wear-resistant and high-temperature resistance: It can withstand more than 10,000 reciprocating frictions of steel brushes, and the long-term crushing friction of airport luggage trolleys and shopping mall trolleys are not easy to cause scratches; it can directly touch the cooking utensils and high-temperature industrial equipment that have just come out of the pot, and do not bulge, do not change color, and do not release harmful substances in case of high temperature.

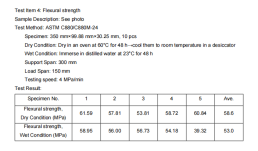

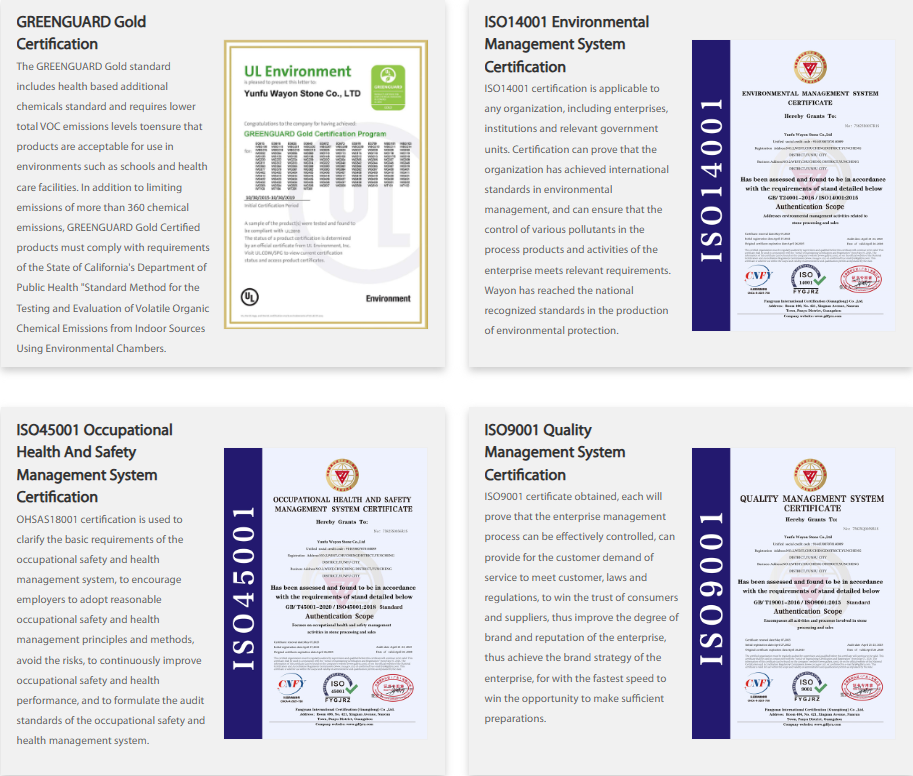

3. Global compliance: barrier-free access to the international market

Wayon stone Zero silica Quartz Stone has passed ISO 19001 (Quality Management System), ISO 45001 (Occupational Health and Safety Management System), ISO 14001 (Environmental Management System) certification, and the whole process from production to delivery meets international management standards; CE EU safety certification (general standard for the safety of building materials); Greenguard American Greenguard certification (indoor air quality gold standard); NSF American food safety certification (food contact scene compliance). Medical treatment, food processing, high-end business and other scenarios can be directly accessed;

4. Engineering efficiency improvement: full chain optimization from production to installation

Large-scale supply: It has four major production and processing bases, with an annual output of more than 3 million square meters, and its business service area covers at home and abroad. It has provided commercial real estate, high-end hotels, home brands and engineering customers in more than 50 countries and regions around the world with one-stop supporting service solutions for stone engineering from material research and development and supply, deepening design to installation guidance.

Engineering cooperation guarantee: full-chain support from supply to landing

For large-scale projects, material selection is not only "product selection", but also "partner selection". Wayon stone Stone provides engineers with a cooperation guarantee covering the whole cycle, making the material landing more worry-free:

- Customized supply: support prefabricated specifications according to project drawings to reduce on-site cutting losses and effectively shorten the construction period;

- Technical service team: equipped with a 20-person engineering technical team to provide preliminary material selection suggestions, medium-term BIM model adaptation, and post-installation guidance, and solve technical problems such as special-shaped machining and splicing accuracy for more than 1,000 projects;

- Warranty and after-sales: If there are non-man-made cracking, empty drums, surface wear and other problems in the process of stone use, Wayon stone can provide professional maintenance services, including filling cracks, partial renovation, etc., to extend the service life of the stone and make the engineering effect last online for a long time.

Wayon stone zero silica quartzite - the definite selection of engineering health materials

For large-scale projects that pursue compliance, efficiency and quality, Wayon stone silica-zero quartz is not only a "zero silica" compliance material, but also a full-cycle solution from design to implementation. With 43 years of engineering experience, global certification system and large-scale supply capacity, Wayon stone is promoting the upgrading of engineering stone with technological innovation, becoming the core partner of engineers and designers to achieve the goal of "safety, efficiency and innovation".

![]()

![]()

Contact Wayon stone Stone https://www.wayon.com/ now to obtain a zero-silica stone test report to empower the value of the project.