What is Silica-Free Stone: A Complete Guide for Safe & Modern Interiors

In recent years, the building materials industry has witnessed a shift toward safer, more sustainable solutions. Among these innovations, silica-free stone has emerged as a leading option, offering a crystalline silica-free surface that protects both workers and end-users while delivering outstanding durability and aesthetics. For businesses and commercial projects, this material represents a reliable, eco-friendly building material that balances safety, performance, and design flexibility.

This guide explores what makes silica-free stone a superior alternative to traditional quartz surfaces, its technical advantages, diverse applications, global market trends, and guidance for selecting the best zero-silica stone for your projects.

Understanding the Health Risks of Traditional Quartz Surfaces

Traditional engineered quartz has been widely used for countertops, wall cladding, and commercial interiors due to its hardness and durability. These surfaces are composed of more than 90% crystalline silica mixed with resins and pigments. While this composition delivers excellent physical performance, it comes with significant health risks.

During cutting, polishing, or fabrication, crystalline silica dust is released. Prolonged exposure to this dust can cause silicosis, an irreversible lung disease, posing serious occupational hazards for stone fabricators. In response, governments worldwide have tightened regulations: Australia banned the production and sale of silica-containing quartz stone in 2024, while Europe and North America introduced stricter workplace safety measures, causing global quartz countertop exports to drop sharply in 2024.

This health crisis has accelerated the adoption of zero silica stone solutions, offering a safer alternative without compromising performance or aesthetics.

Silica-Free Quartz Countertop Supplier

What Makes Silica-Free Stone Different

The primary innovation behind silica-free stone lies in its composition. Unlike traditional quartz, it replaces crystalline silica with amorphous silica or other safe, non-toxic raw materials. Two main production approaches dominate the market:

- Glass-Based Formulation: Uses recycled glass powder or cullet (up to 90%) combined with resins and additives. This approach emphasizes sustainability by reusing industrial waste while providing excellent mechanical properties.

- Sintered Block Formulation: Employs specially processed sintered powders for finer textures, higher strength, and enhanced durability, although at a higher production cost.

Both methods create non-toxic architectural surfaces suitable for commercial, residential, and healthcare applications. Each approach offers unique advantages, addressing different usage scenarios and price points, and together they have accelerated the industrialization of silica-free quartz. The result is a healthy, durable countertop material that meets international safety and environmental standards.

Core Advantages of Silica-Free Stone

Silica-free stone delivers the perfect blend of performance, safety, and sustainability—beyond what traditional quartz can offer.

Exceptional Physical Performance

- Hardness & Wear Resistance: With a Mohs hardness≥5, it outperforms ordinary engineered marble and rivals natural quartz.

- Mechanical Strength: Featuring a bending strength above 50 MPa and compressive strength over 200 MPa, this ensures long-lasting durability in high-traffic and heavy-use settings.

- Thermal & Moisture Stability: Low water absorption (<0.05%) and heat tolerance up to 300°C prevent warping, cracking, or damage, maintaining performance in humid or hot environments.

Modern Zero-Silica Stone Countertop Solutions

Environmental & Health Benefits

- Non-Toxic: Free from crystalline silica, ensuring safe handling for workers and a healthy, worry-free surface for end-users.

- Sustainable: Silica-free stone production consumes less energy, and some products contain up to 90% recycled materials, significantly reducing environmental impact.

- Hygienic & Safe: Certain medical-grade products are antibacterial, stain-resistant, and fire-resistant, making them ideal for hospitals, laboratories, and foodservice areas.

All in all, these combined advantages make silica-free stone the first engineered stone solution to simultaneously meet occupational health, safety, and environmental standards.

Versatile Applications of Silica-Free Stone

Thanks to its safety, environmental benefits, and excellent physical performance, zero-silica stone is rapidly expanding across diverse architectural and interior applications. From high-end residential homes to commercial and hospitality spaces, and from healthcare facilities to public areas, this innovative material is redefining modern standards of quality and durability.

Residential Spaces

In modern homes, silica-free stone has become the preferred choice for kitchen countertops. Compared to traditional quartz, it delivers the same aesthetic appeal and durability while completely eliminating health risks during fabrication and installation. Its superior scratch and stain resistance ensures that daily kitchen activities—such as chopping or handling hot pots—won’t damage the surface, and spills like coffee or red wine can be easily wiped away.

Bathroom vanities also benefit from zero-silica stone’s exceptional moisture resistance. With ultra-low water absorption (<0.05%), it prevents mold growth and water stains, ensuring long-lasting hygiene. Homeowners can choose from over 250 colors and patterns currently available on the market, ranging from solid tones to marble-like designs, accommodating styles from minimalist to luxurious.

Silica-Free Stone Vanity Top Supplier

Commercial and Hospitality Spaces

In high-end hotels and commercial buildings, silica-free stone’s color consistency and availability in large-format panels make it ideal for lobbies, reception desks, and dining surfaces. Leading brands like Wayon Stone have supplied customized silica-free surfaces for luxury projects worldwide, combining durability, minimal maintenance, and long-term color stability—significantly reducing operational costs for commercial spaces.

Healthcare Facilities

Hospitals, laboratories, and other medical environments demand surfaces that are antibacterial, chemically resistant, and easy to clean. Medical-grade zero-silica stone meets these requirements, and its seamless installation eliminates gaps where bacteria could grow. This ensures a safer, more hygienic environment while maintaining the material’s aesthetic and functional performance.

Calacatta Gold Silica-Free Quartz Countertops

How to Choose Silica-Free Stone for Your Project

Selecting the right crystalline silica-free surface ensures optimal performance, durability, and safety, while fully leveraging its design versatility.

Key Considerations

Certification: CE, NSF, SGS reports confirming zero crystalline silica.

Physical Performance

High-quality zero-silica stone should meet or exceed these standards:

- Mohs hardness ≥6 - ensuring scratch resistance

- Water absorption <0.05% - preventing moisture damage and mold growth

- Bending strength >50 MPa - ensuring structural integrity

For heavy-use surfaces like kitchen countertops, a thickness of at least 20 mm is recommended to maintain durability and stability.

Aesthetic Choices

Solid Colors: Ideal for minimalistic or modern interiors, especially in smaller spaces, creating a clean and uniform look.

Marble-like Patterns: Perfect for luxurious designs, with large-format slabs emphasizing natural stone elegance.

Special Effects: Options such as metallic flakes or luminous elements appeal to consumers seeking unique, creative finishes.

White Silica-Free Stone With Gold Veins

Professional Guidance

Fabricators & Installers: Even though silica-free stone significantly reduces health risks, basic dust protection is still recommended during dry cutting or polishing.

Designers & Architects: Large-format panels (e.g., 3200×1600 mm) minimize seams for commercial counters and bars. Thicker slabs (≥30 mm) can serve as structural elements like reception desks or bar tops. Many zero-silica stone suppliers, like Wayon Stone, offer engineering and custom fabrication services to precisely realize complex design concepts.

Healthcare & Laboratory Facilities: Use medical-grade, antibacterial surfaces to meet strict hygiene standards. Special surface treatments inhibit bacteria like E. coli and Staphylococcus aureus, while seamless installations eliminate bacterial growth in joints or gaps.

Zero-Silica Stone Kitchen Countertop

Global Market Trends: Transition from Quartz to Silica-Free Stone

The market for silica-free stone is rapidly evolving, driven by regulatory changes, growing health awareness, and sustainability concerns. The rise of silica-free stone is reshaping the global quartz slab industry, as engineered stone manufacturers shift from traditional quartz to zero-silica technology.

Policy-Driven Growth in the Asia-Pacific

Australia exemplifies the policy-driven shift. Following the July 1, 2024, ban on silica-containing engineered stone, the market has fully embraced zero-silica alternatives. Leading Chinese silica-free stone suppliers, such as Wayon Stone, quickly adjusted their product lines, developing both glass-based and sintered block solutions that comply with Australian standards.

China’s domestic market is also gradually adopting zero-silica stone, reflecting a growing awareness of health and environmental benefits among homeowners, commercial developers, and specifiers.

Australia Market Compliance & Laboratory Validation

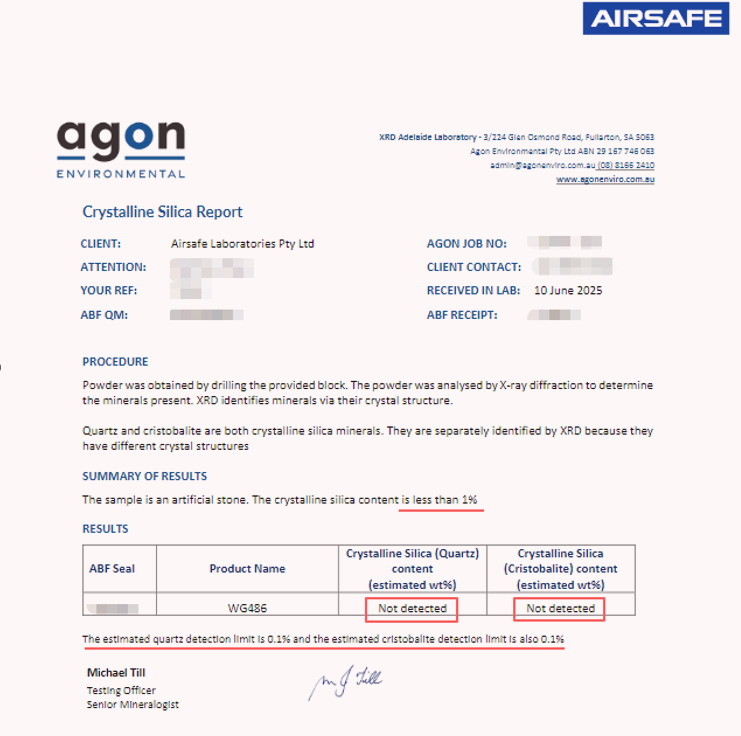

Following the Australian ban on silica-containing engineered stone, Wayon Stone has ensured its silica-free products fully comply with local regulations. Our zero-silica quartz has undergone rigorous testing at Airsafe Laboratories, a reputable Australian institution certified under AS/NZS ISO 17025.

The results show no detectable crystalline silica (quartz or cristobalite), with the lab’s detection limit as low as 0.1%, directly confirming that the actual crystalline silica content in Wayon’s zero-silica quartz is well below our internal control standard of≤0.5% and the industry benchmark of≤1%.

Dual Laboratory Certification:

- Airsafe Laboratories: Australian-based, AS/NZS ISO 17025-accredited

- Agon Environmental: Specialized mineral analysis lab (ABN 29 167 746 063), using XRD crystal structure analysis for precise results.

Wayon Silica-Free Stone - Agon Environmental

This dual certification not only demonstrates the safety of our products but also confirms that Wayon Stone’s zero-silica quartz is not restricted by the Australian CSS ban and can be freely supplied in NSW and other strictly regulated regions, making it one of the few zero-silica materials in its class verified using XRD diffraction analysis.

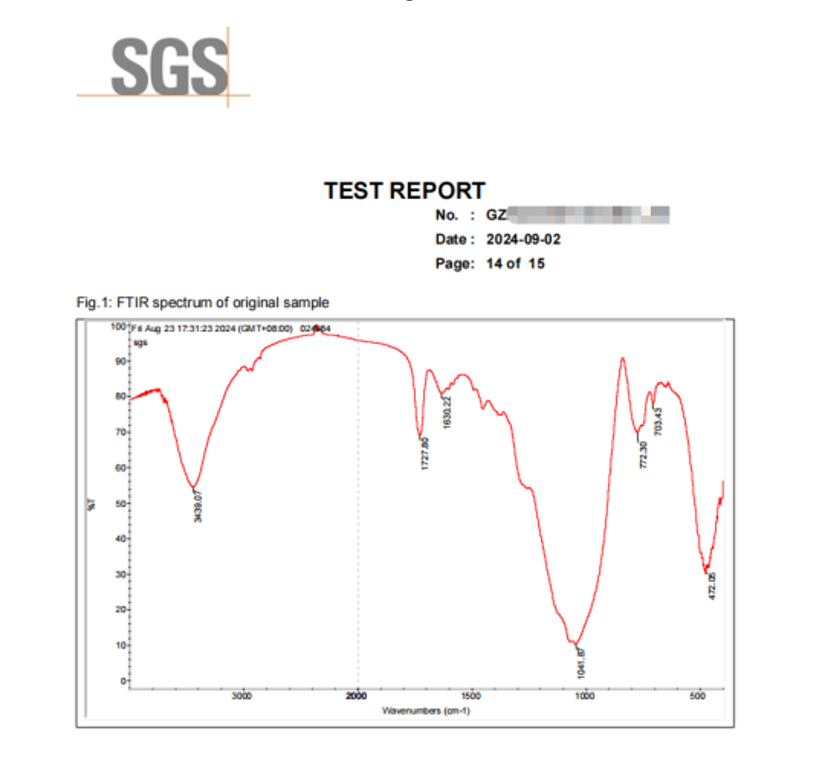

SGS Verification:

Global authority SGS confirmed the composition analysis showing "Characteristic peak of quartz (crystalline silica) was not found", further validating our zero-silica claim. (Feel free to contact us to receive the full quartz test reports.)

Wayon Silica-Free Stone - SGS Verification

In the broader market, zero-silica quartz products are generally 20–30% more expensive than traditional quartz surfaces. However, through technological innovation, precise raw material control, and stable large-scale production capacity, Wayon Stone has optimized the cost premium to a competitive 10–20%, while ensuring superior performance and safety standards.

Adoption in Europe and North America

While adoption in Europe and North America has been slower, the trend is increasingly positive. Being one of the top silica-free stone companies in China, Wayon Stone has expanded its international presence through trade shows in the U.S., Dubai, and other regions, gradually establishing global distribution networks. Focusing on product differentiation, the Calacatta zero-silica series from Wayon Stone was launched to replicate the look of natural marble while offering the safety and durability of silica-free surfaces, successfully entering high-end residential and commercial markets in Europe and the US.

Europe’s stringent environmental and health standards provide a natural growth opportunity. Industry data indicate that leading zero-silica stone suppliers like Wayon Stone have achieved annual revenue growth rates of around 50% over the past seven years, largely driven by the development of neutral-toned (white and gray) zero-silica stone products that complement modern minimalist European design trends.

Grey Silica-Free Quartz Stone Top Supplier

Challenges Facing the Zero-Silica Stone Industry

Despite strong growth potential, the silica-free stone industry faces several challenges:

- Cost Pressures: Zero-silica raw materials are 30–50% more expensive than traditional quartz, leading to higher retail prices and limiting adoption. Sintered block formulas, while offering superior performance, are particularly sensitive to raw material price fluctuations.

- Technical Maturity: Glass-based zero-silica stones, though more cost-effective, may experience warping or deformation, affecting yield. Many silica-free stone manufacturers are optimizing formulations and coupling technologies, but no universal production standard yet exists.

- Lack of market awareness: Many distributors and end-users remain unaware of the health risks of crystalline silica or the benefits of zero-silica stone. Increasing education and industry collaboration is essential to improve adoption.

Future Technological Trends In Silica-Free Stone

Material innovation will drive the next stage of zero-silica stone development. As a leading silica-free stone factory, Wayon Stone invests in smart manufacturing technologies, including fully automated production lines with precise temperature and pressure control to enhance product consistency and efficiency. Digital color systems enable flexible, small-batch, multi-variety production, catering to personalized design demands.

Sustainability will play an increasingly important role in the zero-silica stone industry. Using recycled materials, such as crushed glass, not only reduces production costs but also aligns with global environmental trends. As a professional silica-free stone company, Wayon Stone is investing in product life cycle assessments and carbon footprint tracking, making sustainability a key differentiator in future market competition.

Professional Quartz Stone Manufacturer in China

Future Outlook: Market & Policy

Australia’s 2024 ban on silica-containing engineered stone is likely just the beginning. As silica-related health cases continue to emerge, Europe and North America may introduce similar restrictions within the next 2–3 years. This regulatory momentum is expected to accelerate global adoption of zero-silica technology, giving early movers a significant competitive advantage.

Industry experts predict that by 2029, zero-silica stone could capture over 30% of the global engineered stone market, exceeding 50% in developed countries. This growth will coincide with industry consolidation, rewarding companies with strong technological expertise and established brand reputations.

Conclusion

Silica-free stone represents the next generation of engineered surfaces, combining health, sustainability, and design excellence. It eliminates the risks associated with crystalline silica, ensures compliance with international standards, and meets the aesthetic and functional demands of modern interiors.

Wayon Stone, a leading engineered stone supplier in China, provides high-quality zero-silica stone solutions for commercial projects, healthcare facilities, and premium residential spaces. Businesses that adopt these surfaces today gain a competitive edge in safety, sustainability, and long-term performance, while contributing to a healthier built environment.

To learn more about Wayon Stone’s silica-free stone solutions for your next project, contact our team today!