Why Is Silica-Free Stone Ideal for Schools, Hospitals, and Laboratories?

In engineering construction today, material selection is no longer only about strength or appearance. Health compliance, long-term safety, and regulatory risk are becoming just as important, especially in public buildings like schools, hospitals, and laboratories.

When the Australian government officially implemented the ban on artificial stone containing silica on July 1, 2024. This is where silica-free stone, also known as zero silica quartz stone, has moved from being an alternative to becoming a preferred choice.

The Hidden Risk of Silica in Public Buildings

During the cutting, grinding, and installation of traditional quartz stone, respirable crystalline silica dust is released. These particles are extremely small, typically 1–5 microns, small enough to pass through standard protective masks and penetrate deep into the lungs. In construction zones, it directly affects workers. Renovations, repairs, and daily wear can still release fine dust over time.

Silica-free stone removes this risk at the source. There is no crystalline silica involved, which means no silica dust during processing, installation, or future maintenance.

Why Schools Need Silica-Free Stone?

Schools are one of the most sensitive building types, and exposure standards are naturally stricter. Silica-free quartz stone works well in:

- Classroom floors and walls

- Science lab countertops

- Washrooms and corridors

- Cafeterias and food preparation areas

With water absorption ≤0.01%, Wayon Stone silica-free quartz does not absorb moisture or harbor bacteria, making cleaning easier and reducing long-term hygiene risks. It also resists common school cleaning chemicals and disinfectants, so daily maintenance does not degrade the surface.

Durability matters too. High foot traffic, backpacks, carts, and frequent cleaning all add up. With a Mohs hardness of 6–7 and strong wear resistance, silica-free stone handles this kind of abuse without frequent replacement, which helps schools control maintenance budgets over decades, not just years.

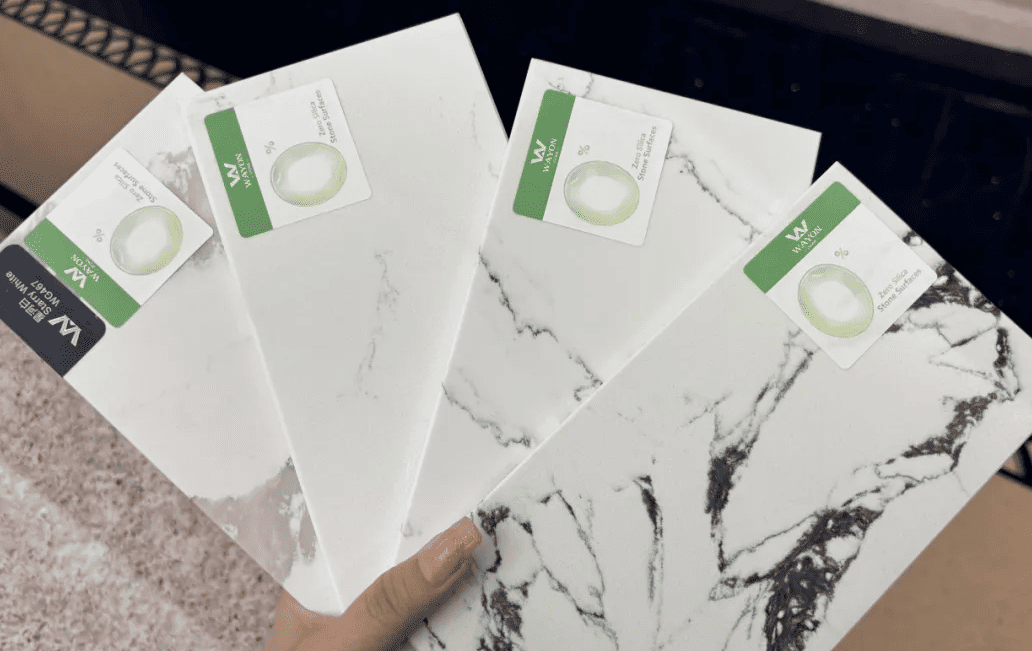

Australia Certified Zero-Silica Quartz

Hospitals and Clinics Demand More Than Beauty

In healthcare environments, material failure is not just cosmetic — it can affect safety and infection control. Hospitals and clinics require materials that are:

- Non-porous

- Easy to disinfect

- Resistant to chemicals

- Stable under temperature changes

Wayon Stone zero silica quartz stone is designed for exactly these conditions. Its chemical resistance allows long-term exposure to disinfectants and detergents without surface damage. It is critical in operating rooms, laboratories, nurse stations, and patient rooms where aggressive cleaning is routine.

The material’s compressive strength (175MPa dry / 163MPa wet, ASTM C170) and bending strength (ASTM C880) ensure stability even in high-load areas. Hospital corridors, equipment zones, and waiting halls often carry heavy rolling loads. Silica-free stone can withstand uniform loads up to 300kg/m², making it suitable for large medical facilities.

And perhaps most importantly, zero silica content aligns with occupational health standards. Medical buildings are increasingly audited not only for patient safety but also for the long-term health of staff.

Zero Silica Stone

Laboratories: Where Material Performance Is Tested Daily

Laboratories are unforgiving spaces. Surfaces must survive chemical spills, heat, friction, and constant use. Silica-free quartz stone performs well in:

- Research laboratories

- University science buildings

- Medical testing labs

- Pharmaceutical facilities

Wayon Stone’s material can withstand over 10,000 cycles of steel brush friction without visible wear. It matters when equipment is moved repeatedly across work surfaces. The stone also tolerates direct contact with high-temperature tools and instruments, without bulging, discoloration, or releasing harmful substances.

For labs working with food samples or chemicals, NSF food safety certification and Greenguard indoor air quality certification provide extra assurance that the material is safe in controlled environments.

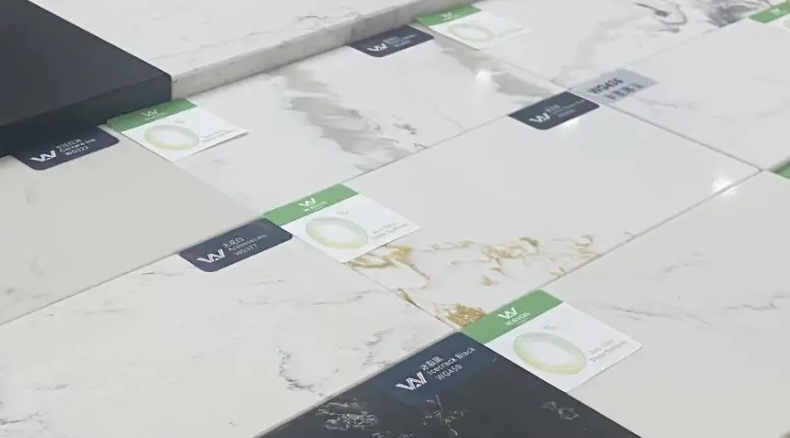

Silica-free Stone Manufacturer

Global Compliance Is No Longer Optional

For international projects, compliance is not a bonus — it is a requirement. Wayon Stone zero silica quartz stone meets:

- ISO 9001 Quality Management

- ISO 45001 Occupational Health and Safety

- ISO 14001 Environmental Management

- CE certification for EU markets

- Greenguard certification for indoor air quality

- NSF certification for food-contact applications

Global compliance makes it easier for architects and developers to specify the same material across schools, hospitals, laboratories, airports, and commercial buildings in different regions without redesigning for each market.

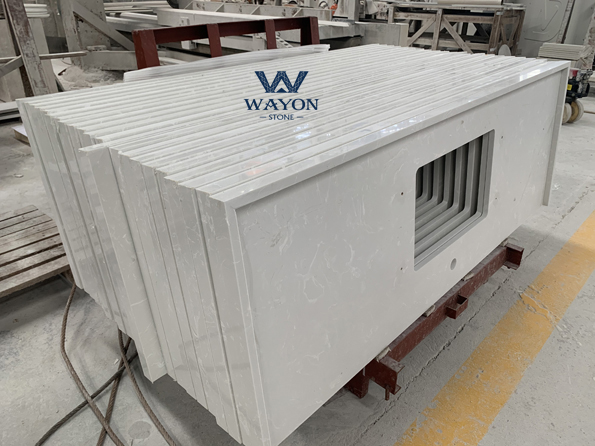

Engineering Efficiency Matters in Large Projects

Material choice affects timelines just as much as design. Wayon Stone operates four major production and processing bases, with an annual capacity exceeding 3 million square meters. This scale supports large public projects where consistent color, batch stability, and delivery schedules are critical. We also offer:

- Prefabricated sizing based on project drawings

- Reduced on-site cutting and waste

- Shorter construction periods

A dedicated 20-person engineering technical team supports projects from early material selection and BIM coordination to installation guidance. For complex shapes, splicing accuracy, or special applications, this support reduces risk during execution.

Long-Term Partnership, Not Just Material Supply

For schools, hospitals, and laboratories, stone is expected to last decades.

Wayon Stone provides after-sales and maintenance services for issues such as non-human cracking, surface wear, or hollowing. Services include crack filling, partial renovation, and surface restoration, helping projects maintain performance and appearance over time.

The full-cycle support is why many engineers see material selection as partner selection, not just procurement.

Why Wayon Stone Is an Ideal Choice?

With 43 years of engineering experience, global certifications, and a strong focus on health-driven innovation, Wayon Stone is helping redefine what engineering stone should be in sensitive public spaces.

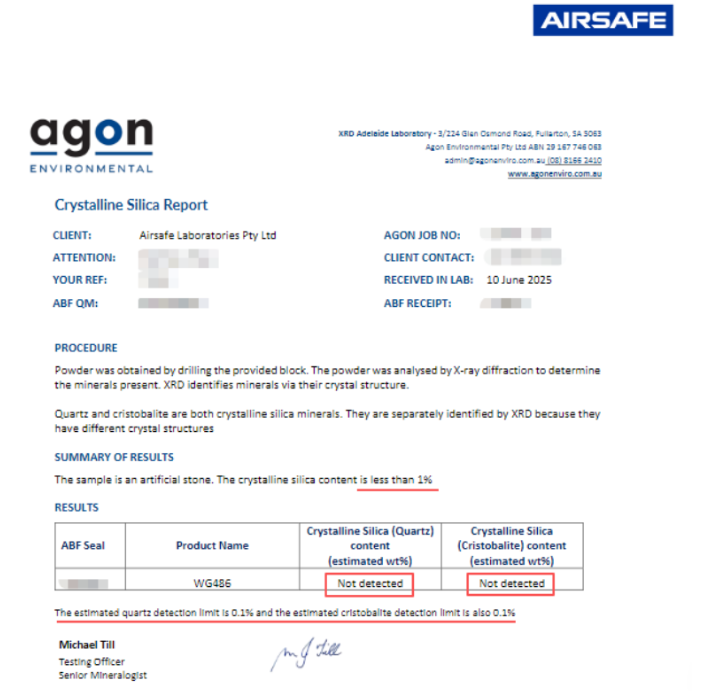

True Zero Silica, Verified by Authorities

Wayon Stone silica-free quartz is not just “low silica”, but true zero silica confirmed by independent testing. According to the test report from Airsafe Laboratories (Australia), crystalline silica minerals including quartz and cristobalite were “Not Detected” in Wayon Stone quartz products. The XRD detection limit of the laboratory is only 0.1%, which proves that the actual crystalline silica content is far below Wayon Stone’s internal control standard of ≤0.5%, and significantly stricter than the common industry level of ≤1%.

Double laboratory endorse:

- Airsafe Laboratories: a well-known testing institution in Australia, with AS/NZS ISO 17025 certification;

- Agon Environmental: Professional Mineral Analysis Laboratory (ABN 29 167 746 063), using XRD crystal structure analysis;

This result confirms that Wayon Stone silica-free quartz is not restricted by the Australian CSS ban, including highly regulated regions such as NSW, and is one of the few zero silica quartz materials verified by XRD diffraction testing.

图片地址

https://img.yigetechcms.com/109/source/Zero_silicon_detection_report1_73572.png

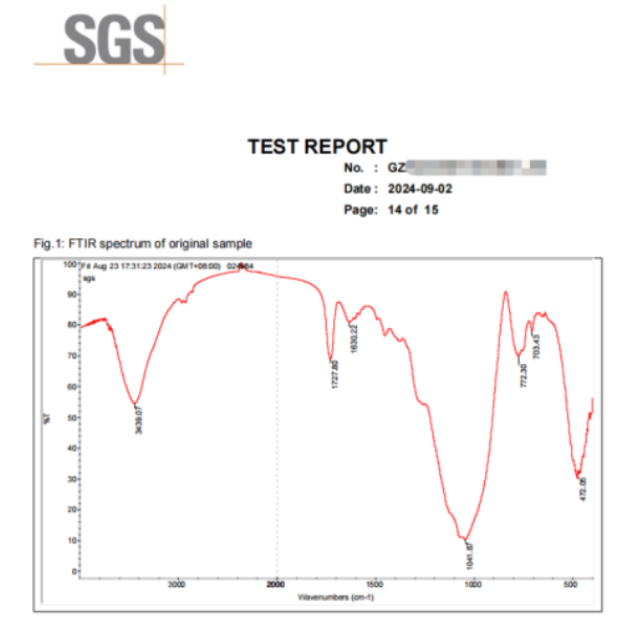

Backed by SGS Material Analysis

Component analysis by SGS further confirms that no characteristic peak of quartz (crystalline silica) was found. The material is composed of 89% glass and 11% unsaturated polyester (UP resin), providing a clear and transparent explanation of its zero silica structure. With verification from both Australian and global authorities, Wayon Stone offers a silica-free solution that meets strict health, safety, and compliance requirements for schools, hospitals, and laboratories.

Cost Efficiency Through Scaled Innovation

In the current market, most silica-free or zero silica stone products are typically priced 20–30% higher than traditional quartz, mainly due to complex formulations and limited production capacity. Through continuous technology innovation, strict raw material control, and stable large-scale output, Wayon Stone has successfully optimized the cost structure of silica-free quartz.

Under the same engineering-grade performance and compliance standards, Wayon Stone silica-free quartz is generally priced at a more controlled level, with a premium of approximately 10–20%, making true zero silica materials more accessible for large-scale projects without compromising safety or quality.

If your next project values health, compliance, and long-term performance, Wayon Stone silica-free quartz is a solution worth serious consideration.

Conclusion: Building Healthier Spaces with Wayon Stone

As regulations tighten and expectations rise, silica-free stone is becoming the new standard for schools, hospitals, and laboratories. Wayon zero silica quartz combines safety, engineering performance, and global compliance into one practical solution.

For architects, engineers, and developers planning future-ready public buildings, Wayon Stone is not just a supplier, but a long-term partner.

Contact Wayon Stone today to explore how silica-free quartz stone can support your next project with confidence.