Zero Silica Stone: Revolutionizing Healthy and Eco-Friendly Building Material

In today's architectural decoration materials sector, a health and environmental revolution is quietly emerging. With growing global awareness of occupational health, safety, and environmental protection, Zero Silica Stone has rapidly become an industry focal point as a innovative alternative to traditional engineered quartz. This groundbreaking material not only addresses the long-standing issue of silica risk but also redefines standards for premium architectural surfaces with its exceptional physical properties and eco-friendly characteristics. This article provides a comprehensive analysis of Zero Silica Stone's technical features, market advantages, application, and future trends, offering deep insights in this game-changing material.

Industry Background and Health Crisis Driving Zero Silica Stone Adoption

Engineered quartz has been mainstream choice in architectural decoration for two decades, widely used in kitchen countertops, bathroom vanities, wall, and commercial spaces. Traditional quartz contains over 90% crystalline silica (quartz sand/powder) mixed with resins and pigments. While this high-silica formula provides excellent hardness and durability, it also creates serious health hazards. During cutting and polishing processes, the released silica dust can cause irreversible lung damage—silicosis—a devastating occupational disease.

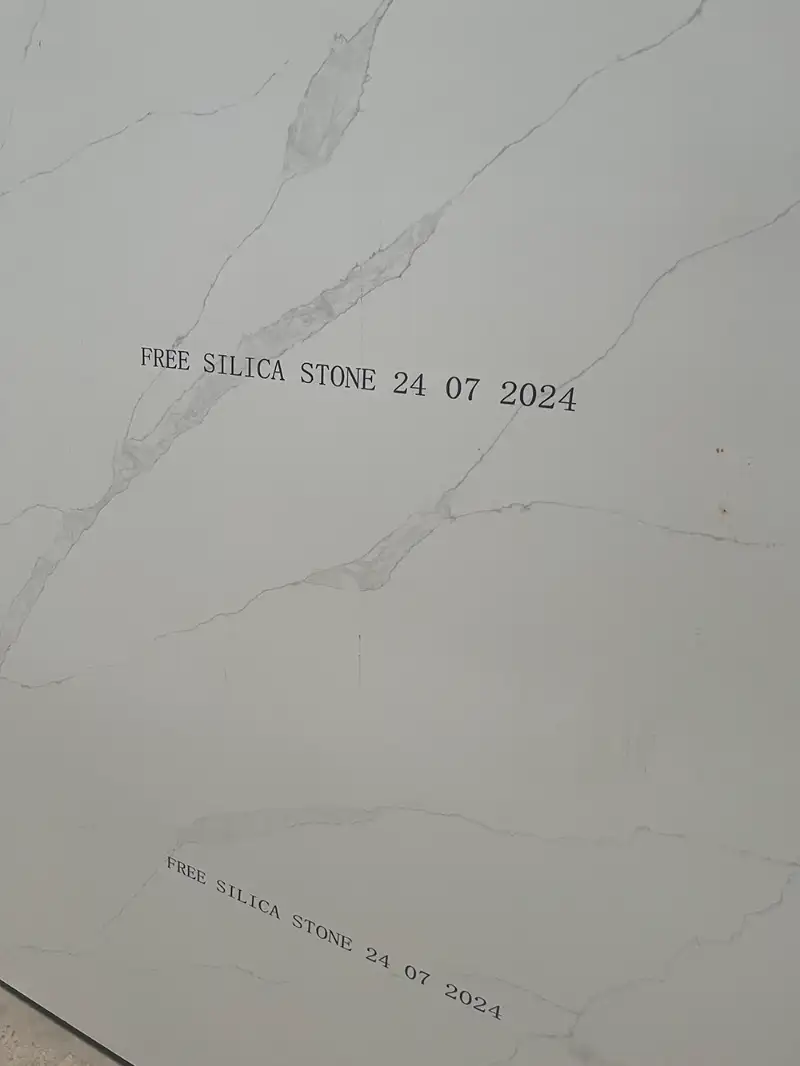

The global outbreak of silicosis among artificial stone workers has alarmed governments worldwide. Australia has reported over 570 cases since the first diagnosis in 2015, while countries like Israel and Spanish documented concentrated outbreaks as early as 2009. This health crisis directly prompted the Australian government to ban silica-containing artificial stone production and sales effective July 1, 2024. Following similar policies in other countries, global quartz countertop exports declined sharply in 2024, while prices for compliant "zero-silica" products rose against the trend.

In this context, Zero Silica Stone emerged as a critical solution. By completely eliminating crystalline silica and using amorphous silica and other materials instead, this innovation eradicates silicosis risk at its source. Zero Silica Stone are protects workers' health during fabrication or installation while providing safer living environments for end-users, fully complying with international environmental standards and increasingly stringent health regulations.

Technological Innovations and Core Advantages

Zero Silica Stone's breakthrough primarily lie in a material formulations and manufacturing processes. Unlike traditional quartz, it uses amorphous silica as the primary filler—a material commonly found in glass products with stable molecular structures that pose minimal risk to human lungs. Combined with unsaturated polymer resins, coupling agents, and other additives through precise formulations and advanced mixing technologies, it creates a new composite material that combines safety with outstanding physical performance.

Revolutionary Material Formulations

Current Zero Silica Stone technologies mainly follow two approaches:

- Glass-based formula: Uses up to 90% recycled glass cullet/powder with resins and additives, achieving remarkable resource recycling and environmental benefits.

- Frit-based formula: Employs specially made frit sand/powder, producing materials with finer textures and higher strength, though at greater production costs.

These complementary technologies serve different applications and price points, jointly advancing Zero Silica Stone's industrialization.

Exceptional Physical Properties

Zero Silica Stone excels in multiple key performance indicators:

- Hardness & wear resistance: Mohs hardness 5-7, comparable to natural quartz sand and far superior to ordinary artificial marble.

- Mechanical strength: Flexural strength up to 52.7MPa, compressive strength exceeding 200MPa, ensuring crack and deformation resistance.

- Weather stability: Water absorption below 0.02%, thermal stability withstands 300°C, resisting performance degradation from temperature changes or humidity.

- Hygienic properties: Medical-grade products feature antibacterial, stain-resistant, and fire-retardant qualities, ideal for school hospitals and laboratories.

Dual Health and Environmental Protection

The core value of zero-silica technology lies in completely eliminating traditional quartz's health risks. Using amorphous silica removes silicosis hazards, allowing safe fabrication and installation without special protective measures. Additionally, Zero Silica Stone production consumes less energy, with some products incorporating up to 90% recycled materials, further reducing environmental footprints. These characteristics make it the first artificial stone solution simultaneously meeting occupational health and environmental requirements.

Diverse Applications

With its safety and performance advantages, Zero Silica Stone is rapidly penetrating various architectural decoration segments, redefining quality standards from residential to commercial spaces, medical facilities to hospitality venues.

Residential Applications

In homes, Zero Silica Stone has become the preferred choice for kitchen countertops. While maintaining equivalent aesthetics and durability to traditional quartz, it completely eliminates health risks during fabrication and installation. Common kitchen activities like chopping won't leave marks on Zero Silica surfaces, and their superior stain resistance prevents liquids like coffee or wine from penetrating, requiring only simple wiping for maintenance.

Bathroom vanities represent another important application. Zero Silica Stone's extremely low water absorption (<0.05%) effectively prevents mold growth and water stains in humid environments. Consumers can choose from over 250 colors and patterns ranging from solid colors to marble-look designs, accommodating styles from minimalist to luxurious.

Commercial and Public Space Solutions

In luxury hotels and commercial venues, Zero Silica Stone's color consistency and large-scale supply capability make it ideal for reception desks, dining tables, and other surfaces. Leading brands like Wayon Quartz have successfully applied zero-silica products in global five-star hotel projects, where wear resistance and color stability significantly reduce maintenance costs and.

The medical field particularly values Zero Silica Stone. Hospitals require materials with special antibacterial and chemical-resistant properties. Medical-grade Zero Silica Stone has been successful applied in walls and floors of multiple hospitals, meeting strict hygiene standards while eliminating bacterial breeding grounds through seamless installation.

Creative Design and Customization

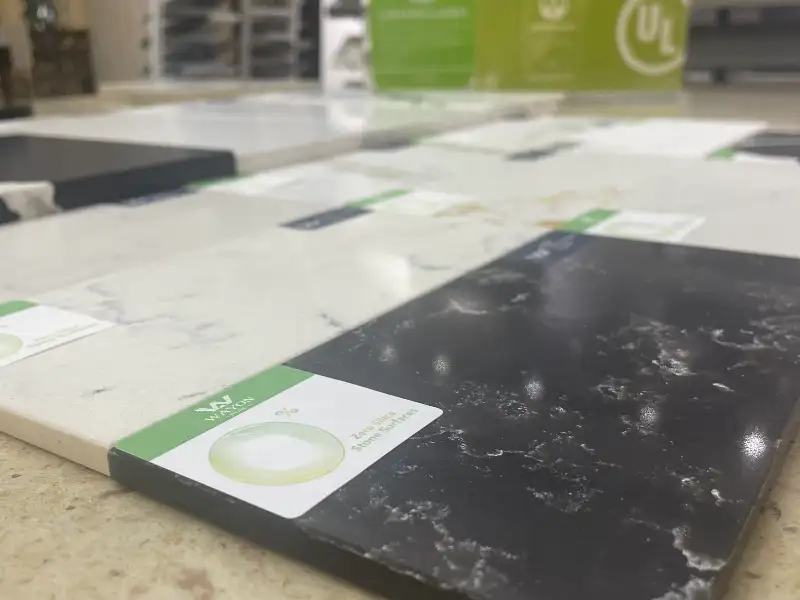

Zero Silica Stone offers a remarkable design flexibility. Large-format slabs (up to 3200x1600mm) minimize seams for continuous visual effects. Customization services provide options for colors, textures, and thicknesses (12-60mm), with edge treatments including straight, rounded, or beveled profiles. Some premium products incorporate innovative elements like luminous particles or metallic finishes, expanding design possibilities.

Global Market Landscape and Leading Brands

The rapid rise of Zero Silica Stone is reshaping the global engineered stone industry. As Australia's ban takes effect and and other countries tighten regulations, traditional quartz manufacturer are transitioning to zero-silica technologies, triggering industry realignment.

Asia-Pacific Market Growth

Australia's market transformation is most representative. Since the July 2024 ban, the market has fully shifted to zero-silica products. Chinese exporters like Wayon Stone quickly adjusted product structures, developing glass-based and frit-based Zero Silica Stone meeting Australian standards. Though 20-30% more expensive than traditional quartz, these compliant products maintain strong demand due to their health advantages.

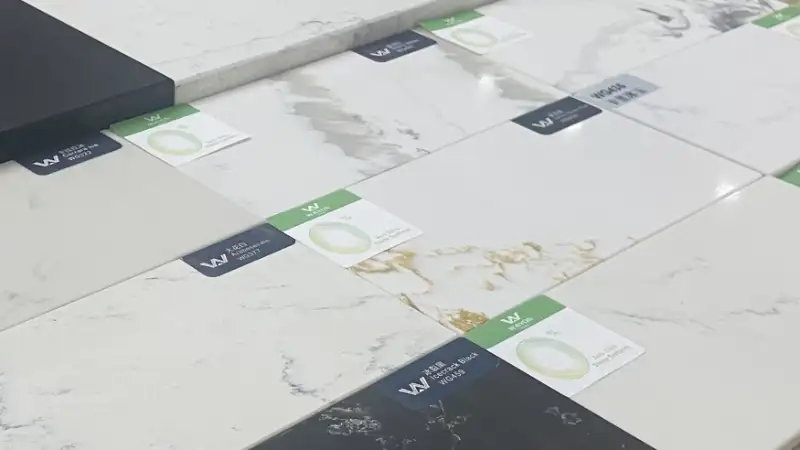

China's domestic market acceptance is also steadily increasing. Wayon Quartz participates in industry exhibitions and technical seminars to promote zero-silica concepts. As a leading export brand, its products represent top global environmental standards, with innovative designs winning widespread acclaim.

European and American Market Competition

Western markets are adopting Zero Silica Stone more gradually but show clear growth trends. Chinese manufacturers like Wayonstone have established international distribution networks by attending trade shows in the U.S. and Dubai. Their differentiated products, such as Calacatta series mimicking natural marble while featuring zero-silica properties, successfully penetrate high-end residential and commercial projects.

Europe's stringent environmental and health standards naturally favor Zero Silica Stone. Industry data shows leading companies like Wayonstone achieving 50% annual revenue growth over seven years, driven by continuous development of white and gray-toned products that complement modern minimalist designs.

Leading Brand Analysis

China's Wayon Quartz and Spain's Silestone represent two distinct approaches to Zero Silica Stone innovation:

Wayon Quartz, established in 1982, has grown into a global player with four production bases in China and annual output exceeding 3 million square meters. As a national high-tech enterprise, it helped formulate China's "Artificial Stone Technical Specification" industry standard. Its zero-silica series uses amorphous silica through advanced vacuum vibration compaction and high-temperature curing, achieving Mohs hardness 6-7, water absorption 0.01%, and compressive strength 207MPa. With NSF, CE, and Greenguard certifications, Wayon products qualify for LEED and WELL building credits, having been applied in projects like Montreal Modern Apartments and Shanghai Lanting Luxury Residences.

Silestone, developed by Spain's Cosentino Group in 1989, has dominated premium countertop markets with its 93% natural quartz and 7% resin composition featuring vacuum compaction technology. Its five key attributes—scratch-proof, stain-proof, heat-proof, durable, and antibacterial (with Microban technology)—redefined surface standards. and Silestone offers diverse colors and three finishes (polished, matte, and textured), earning recognition including Time Magazine's "Coolest New Gadgets" for its built-in antimicrobial protection. While maintaining premium pricing (reaching $2,000/sqm in the U.S.), Silestone has successfully penetrated China's high-end residential market since 2002.

Technical Comparison: Eastern and Western Innovation Paths

Wayon Quartz and Silestone pursue different technological routes in zero-silica development. Wayon employs a glass based formula using up to 90% recycled glass, lowering costs while promoting sustainability. Silestone maintains a high-purity quartz base, removing metallic impurities through special purification processes to ensure non-radioactive materials preserving quartz's natural translucency.

In physical properties, each excels differently. Wayon shows outstanding mechanical strength with flexural strength reaching 84.2MPa, while Silestone's dense network structure provides superior and surface hardness and impact resistance. These differences suit varied applications—Wayon for high-stress projects, Silestone for design-focused residential kitchens.

Antibacterial technologies also differ. Wayon achieves basic antimicrobial effects through dense material structure, whereas Silestone incorporates active Microban protection. This reflects their distinct market positions—Wayon focusing on engineering solutions, Silestone on premium lifestyle enhancements.

Both brands invest heavily in surface treatment innovations. Wayon develops diverse textures and finishes from high-gloss and matte, while Silestone pioneered three surface options: polished, suede, and volcanic. continuous innovation demonstrates leading brands' shared belief in design-driven growth.

Market Strategies and Global Distribution

Global expansion approaches differ between Wayon Quartz and Silestone. Leveraging China's stone industry cluster advantages, Wayon built a complete supply chain covering raw materials, R&D, production, and sales, exporting to over twenty countries. Responding to Australia's ban, Wayon quickly adapted products to meet local standards, gaining market recognition despite 20-30% price premiums.

Silestone dominates Western premium markets through brand prestige and design excellence. Since entering China in 2002, it has succeeded in luxury residential projects in major cities. Its U.S. pricing reaches $2,000/sqm meter, making it synonymous with high-end kitchens. This positioning provides strong pricing resilience during economic fluctuations.

In channel development, Wayon established comprehensive systems including quarries, R&D centers, production bases, and marketing centers, with a flagship showroom in Foshan. Silestone focuses more on collaborating with top designers to penetrate high-end markets. These strategies reflect their distinct brand positioning and segmentation choices.

Facing digital transformation, both brands accelerated online marketing. Wayon enhances technical influence through industry platforms, while Silestone emphasizes social media and designer community engagement. These differentiated digital approaches effectively reach their respective target audiences.

Application Innovations and Design Trends

Zero Silica Stone applications continue expanding beyond traditional countertops and vanities. Wayon Quartz's exceptional performance makes it ideal for commercial spaces like hotel lobbies and reception desks. Its engineering customization services enable complex designs, with large-format slabs minimizing seams for seamless visuals.

In healthcare, Zero Silica Stone's sterile properties prove invaluable. Wayon's medical-grade products feature specialized antibacterial and chemical-resistant functions, successfully applied in hospital walls and floors. Seamless installation eliminates bacterial breeding grounds, providing safer medical environments.

Silestone continues innovating in luxury homes, transforming kitchen countertops into artistic centers. Its color variety and texturing technologies allow highly personalized spaces. Notably, its antibacterial properties make it perfect for "kitchen garden" concepts combining planting and cooking areas, meeting post-pandemic health-conscious demands.

Design trends show both brands capturing naturalism-meets-minimalism fusion. Wayon's Carrara and color series blend natural stone patterns with modern aesthetics. Silestone's computer-mixed six-color technology creates deeper, layered natural look. This modern interpretation of natural beauty is becoming premium materials' universal language.

Future smart home integration may combine Zero Silica Stone with IoT technologies, potentially embedding sensors or interactive lighting edges. Wayon and Silestone's material expertise will support such cross-disciplinary innovations.

Purchasing Guide and Industry Recommendations

When selecting Zero Silica Stone, certifications are primary quality indicators. Premium products should have CE, NSF, and SGS reports confirming environmental compliance and food safety (especially for countertops), with crystalline silica content listed as "not detected."

Physical specifications are equally crucial. Quality Zero Silica Stone should feature: Mohs hardness ≥6, water absorption <0.02%, flexural strength >50MPa. For high-use areas like kitchens, recommend minimum 20mm thickness ensuring structural integrity. Both Wayon and Silestone exceed these benchmarks, offering reliable assurance.

Design selections should complement overall styles. Current trends include:

- Solid colors: Ideal for modern minimalism, especially small spaces, creating clean unified looks

- Marble-look patterns: Suit luxurious decors, where large slabs showcase natural stone's grandeur

- Special effects: Like metallic flecks or luminous elements, appealing to style-conscious younger buyers

For industry players, the zero-silica transition presents both challenges and opportunities. Manufacturers should increase R&D investment in amorphous silica formulations to reduce costly imported material dependence. Strengthening supply chains by expanding into upstream materials enhances security. Obtaining international certifications prepares for potential regulatory changes. Developing differentiated products avoids price wars, building brand premiums through design and technology.

Designers and architects can maximize Zero Silica Stone's design flexibility. Large slabs suit commercial counters minimizing joints, while 30mm+ thickness works for structural elements like bars. Wayon's custom engineering services precisely execute complex designs from blueprints.

For hospitals and labs, recommend antibacterial Zero Silica Stone. Specially treated surfaces and staphylococcus growth, with seamless installation further enhancing hygiene—critical protection for sensitive environments.

Conclusion

Zero Silica Stone represents artificial stone's inevitable future. Its adoption will fundamentally improve workers' occupational health while providing safer, greener building material choices. As technology advances and economies of scale emerge, prices will gradually become more accessible, ultimately establishing Zero Silica Stone as the market standard. For consumers, designers, and industry participants alike, understanding and embracing this trend is undoubtedly the wisest choice.