Wayon Stone processing factory

Actual situation of processing and shipping before the new year

2024.1

Wayon Stone

Full sprint

Entering the year-end processing season

High standards and strict requirements

Just to deliver as soon as possible

Delivering the highest quality products to customers

Wayon

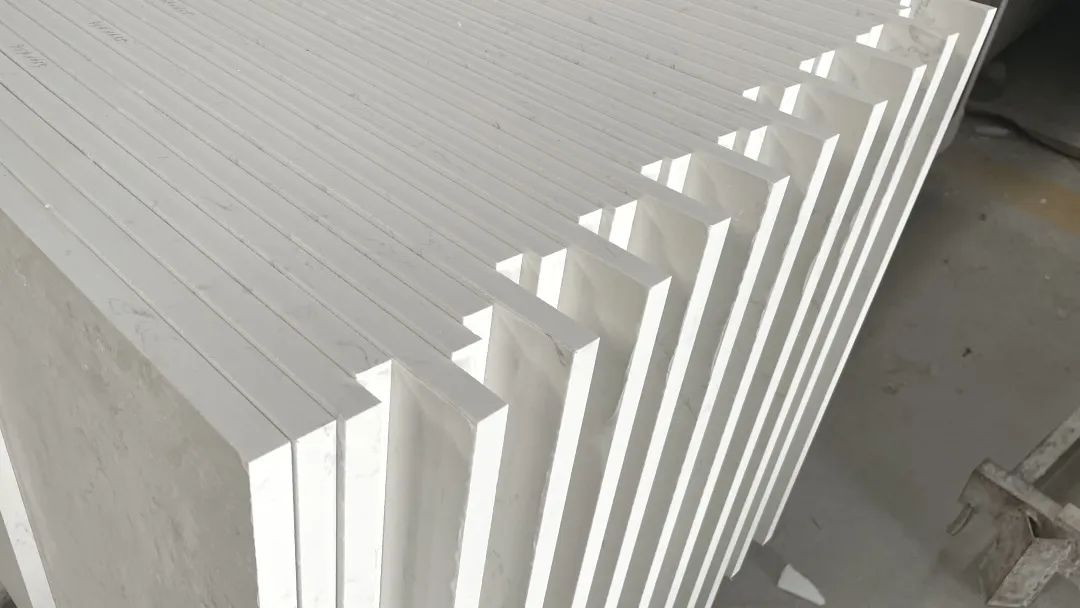

Professional equipment efficiently completes cutting, polishing, and polishing

The Yunfu Wayon Stone Processing Base has a factory area of 6500 square meters and is equipped with 12 Taiwan bridge cutting machines, Italian five axis photo typesetting automatic suction cup bridge cutting machines, Italian automatic edge grinding machines, 2 Taiwan automatic edge grinding machines, a cabinet panel splicing assembly line, 3 CNC drilling machines, 5 high-quality sample machines, and 1 set of 4+8 head line production equipment.

The professional equipment is complete, and these devices use precise digital control technology to perform high-precision and efficient stone cutting, polishing, and polishing work, efficiently processing the required stone product dimensions for customers.

As the end of the year approaches, the Wayon Stone Processing Base welcomes the final processing season of the year, with orders from all parties gathering and demanding new and higher standards and quality. Wayon Stone's professional digital processing equipment greatly provides processing customization efficiency and greatly reduces errors, ensuring customers receive goods on time.

Craftsman spirit takes every processing order seriously

We deeply understand that time is efficiency, and efficiency is quality. Understand the customer's sentiment towards early delivery. In the workshop, in addition to efficient production by machines, it is also necessary for workers to meticulously polish and process details by hand. Weiyang people have always adhered to the value of craftsmanship, and have poured Wayon people's hard work and craftsmanship into every customized product of Wayon.

The Wayon workers infused their craftsmanship into manual polishing. They use professional skills and experience to repeatedly polish every detail of the stone, striving to achieve the highest quality product effect.

Completing delivery tasks within a limited time and scientifically optimizing the process flow is the mission and pursuit of Wayon people. We will control every production process with a more rigorous attitude, striving to combine product quality and efficiency, and take our products to a new level.

Craftsmanship in polishing and shining stones

Wayonpeople work overtime to ensure timely delivery

Wayon

Wayon Processing Interprets the Excellent Charm of Stone

In front of the camera, there are various hand washing countertops, integrated basins, specification boards, and cabinet countertops that have been processed with Weiyang stone recently. They perfectly combine the natural beauty of stone with spatial functionality, injecting an excellent experience into scenes such as kitchen and bathroom spaces.

Quartz stone washbasin processing

Customized specification board according to customer size

Quartz stone washbasin countertops shipped in large quantities

Cabinet countertop panel

Marble large flower green natural stone wash basins are processed and shipped in bulk

Fixed processing of quartz stone washbasin countertop

Wayon

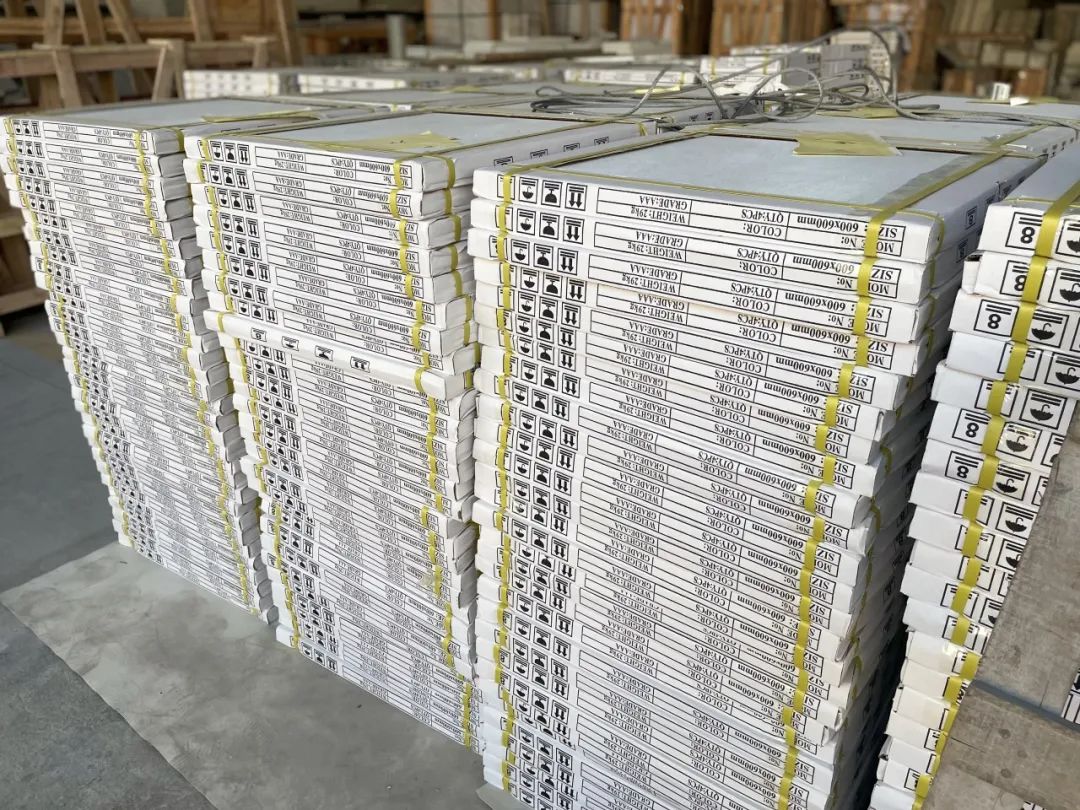

Reinforcement and storage of completed orders, timely shipment and departure

We will package and store the processed products in a timely manner according to customer orders, neatly stacking them together according to order numbers for subsequent shipment and loading.

e are well aware that the customized processing of each stone slab is not easy to come by and is important for customer engineering installation. Therefore, Wayon's packaging box has been carefully designed and fixed with thickened wooden boards, which can effectively prevent collision and damage to the goods during transportation。

Timely container loading upon completion of processing

Fastest delivery time

Wayon Stone has been persisting for many years

Wayon Global, a brand image with consistent quality

For over forty years

Wayon always adheres to

The business philosophy of "integrity and quality"

Provide consumers with

Millions of stone products